In cleanroom HVAC systems, rough filters and fine filters play an important role in maintaining air quality that meets GMP, ISO 14644 or HACCP standards. However, if not replaced at the right time, the filtration efficiency will decrease, causing pollution and wasting energy. So when should rough filters and fine filters be replaced in HVAC systems

- 1. The Role of Pre-Filters and Fine Filters in HVAC Systems

- 2. Factors Affecting Filter Replacement Frequency

- 3. Signs That Indicate a Filter Needs Replacement

- 4. Recommended Filter Replacement Cycle by Industry Standards

- 5. Risks of Not Replacing Filters on Time

- 6. Suggested HVAC Filter Inspection and Maintenance Schedule

- 7. Frequently Asked Questions

- 8. Need Expert Help Replacing HVAC Filters Correctly?

In the operation of HVAC systems in factories, offices and industrial zones, periodic replacement of filter levels such as coarse and fine filters plays a key role. The question is: when should you replace coarse and fine filters in the HVAC system? The correct answer will help you maintain filter performance, reduce energy consumption, and ensure air quality in the working environment. This article will guide you to distinguish the right time, signs of needing replacement, and important criteria to consider when making a decision.

1. The Role of Pre-Filters and Fine Filters in HVAC Systems

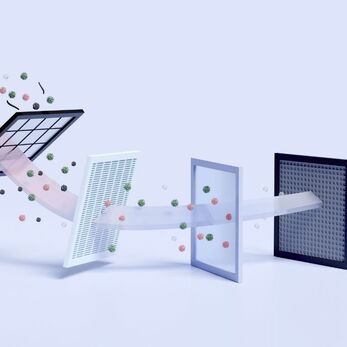

In a cleanroom HVAC system, air filters play a crucial role in controlling air quality and maintaining environmental conditions that meet GMP, ISO 14644, or HACCP standards. The two most common types of filters are Pre-Filters and Fine Filters, each serving a specific function.

Pre-Filters (G2 - G4)

- Main function: Capture large dust particles, hair, fabric fibers, and insects at the initial stage.

- Protective role: Prevent large contaminants from clogging the fan or cooling coils, extending system lifespan.

- Installation position: Typically installed at the return air inlet or inside the AHU unit.

Fine Filters (F5 - F9)

- Main function: Capture fine dust, pollen, mold spores, and bacteria in the 1-5 micron range.

- Precise role: Ensure clean air quality before it enters sensitive production zones.

- Installation position: Placed before HEPA filters or directly at air supply outlets if no HEPA filter is used.

Applications by Industry

|

Industry |

Air Filtration Objective |

Filtration System Characteristics |

|

Pharmaceuticals |

Control of microorganisms and fine dust |

3-stage filtration (pre-medium-HEPA) compliant with EU-GMP |

|

Food |

Odor removal and cross-contamination control |

Common setup: G4 + F8, with activated carbon if odor is present |

|

Cosmetics |

Maintain cleanliness in filling and packing areas |

F8 or F9 filters with positive pressure control |

|

Electronics |

Eliminate particles that can damage circuits |

High cleanliness (ISO 5-6), using F9 + HEPA or ULPA filters |

See more: Important differences in the production of HEPA Filters H13 and H14

2. Factors Affecting Filter Replacement Frequency

There is no fixed interval for replacing pre-filters or fine filters in HVAC systems. Filter lifespan depends on several factors related to the environment, equipment, and production requirements.

Air Pollution Level at Intake

- Facility location: Plants near construction sites, highways, or industrial areas have more dust and require more frequent filter changes.

- Season: Dry and windy seasons typically increase dust load.

- Industry type: Sectors such as pharmaceuticals and electronics demand higher cleanliness, thus more frequent replacements.

HVAC Operating Frequency

|

Operating Condition |

Effect on Filter |

|

Continuous 24/7 operation |

Filters clog faster and require earlier replacement |

|

Intermittent or shift-based operation |

Filters last longer, replacement time is flexible |

|

Long shutdown periods |

Filters may grow mold if not maintained properly |

Required Cleanroom Class

- ISO 5-6 / GMP Class A-B: Require very strict air cleanliness—filters must be inspected and replaced more often.

- ISO 7-8 / GMP Class C-D: Longer replacement intervals if test results remain compliant.

|

Cleanroom Class |

Suggested Replacement Frequency |

|

ISO 5-6 (electronics, aseptic filling) |

Fine & HEPA filters: monthly inspection |

|

ISO 7-8 (packing, storage areas) |

Pre-filters: every 3 months; Fine filters: every 6 months |

Filter Type

- Pre-Filter (G2-G4): Replace every 1-3 months.

- Fine Filter (F5-F9): Lifespan around 4-6 months depending on conditions.

- HEPA Filter (H13-H14): Replace based on pressure drop and DOP test results, not on a fixed schedule.

Note: Using low-quality or undersized filters will shorten lifespan and reduce performance.

See more: Latest price list of Heat-resistant HEPA filters used in Cosmetic factories

3. Signs That Indicate a Filter Needs Replacement

Operators should not rely solely on scheduled replacement intervals. Regular inspections help detect issues early and prevent contamination risks.

|

Sign |

Cause |

Consequence if Ignored |

|

Abnormally high pressure drop |

Filter heavily clogged with dust |

- Increased energy consumption - Reduced airflow - AHU motor overload |

|

Filter color turns dark gray or black |

Dust accumulation over time reduces efficiency |

- Risk of backflow contamination - Loss of microbial filtration |

|

Failed ISO/GMP inspection |

Poor filter performance, exceeded pressure limits |

- Audit failure - Production interruption (critical in pharma plants) |

|

Unpleasant odor at air outlet |

Mold growth or microbial contamination |

- Cross-contamination, especially in food & cosmetics sectors |

|

Dust found in clean area |

Filter damaged or improperly installed |

- Product quality compromise - Increased contamination control costs |

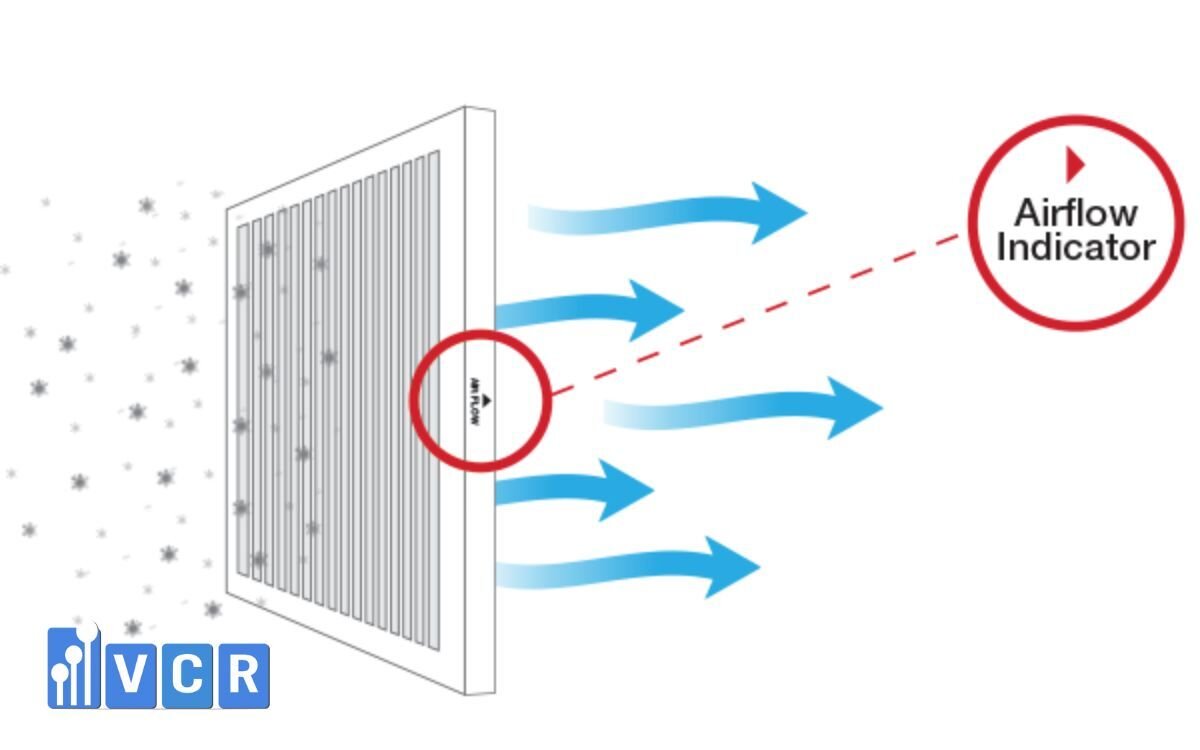

Tip: Use differential pressure gauges (dual-needle or digital sensors) to monitor filter status continuously.

4. Recommended Filter Replacement Cycle by Industry Standards

Filter replacement frequency should be based on cleanliness requirements and applicable standards such as GMP, ISO 14644, or HACCP.

|

Industry |

Filter Type |

Suggested Cycle |

Notes |

|

Pharmaceuticals (GMP EU/WHO, ISO 5-7) |

Pre-filter (G4) |

Every 1-3 months |

Depends on dust level and HVAC runtime |

|

Fine filter (F8-F9) |

Every 6 months |

Regular pressure drop monitoring recommended |

|

|

HEPA (H13-H14) |

Test every 6 months, replace every 1-2 years |

Based on DOP test results |

|

|

Food & Cosmetics (HACCP, ISO 22716) |

Pre-filter (G4) |

Every 3 months |

May extend if intake air is clean |

|

Fine filter (F7-F9) |

Every 6-9 months |

Critical for filling and packaging areas |

|

|

Electronics - SMT, Semiconductor (ISO 5-6) |

Fine filter (F9) |

Monthly inspection |

Requires ultra-clean environment |

|

HEPA/ULPA |

Based on pressure drop and performance |

Continuous monitoring via sensors required |

Note: Always combine inspection results, differential pressure data, and visual checks before deciding on replacement to ensure optimal air quality and compliance.

See more: Latest price list of HEPA filters used in food factories

5. Risks of Not Replacing Filters on Time

Delaying air filter replacement in an HVAC system not only affects technical performance but also poses direct risks to product quality, operating costs, and regulatory compliance. Below are the most common consequences:

1. Increased and unnecessary operating costs

When filters become clogged with dust, the pressure drop rises, forcing the fan to increase its power to maintain airflow.

This leads to higher energy consumption, faster motor wear, AHU overload, and increased maintenance costs.

2. Loss of environmental control and higher risk of cross-contamination

Dirty filters can no longer effectively trap dust or microorganisms, resulting in reverse contamination in the cleanroom.

Unstable air pressure allows contaminated air to enter through airlocks or changing rooms, compromising cleanroom integrity.

3. Inaccurate production and testing results

In pharmaceutical or cosmetic production, poor filtration efficiency can:

- Allow fine particles to affect product purity.

- Cause microbiological or analytical test results to fail.

- Lead to GMP audit failure, product recalls, or export restrictions.

4. Regulatory non-compliance and audit failure

Standards such as ISO 14644, GMP (EU/WHO), and HACCP require regular inspection and documented filter replacement.

Failure to replace filters on time may result in the company being marked as “non-compliant with HVAC procedures” during internal or customer audits.

6. Suggested HVAC Filter Inspection and Maintenance Schedule

To ensure filters always perform effectively and meet GMP/ISO standards, companies should establish a regular inspection and maintenance schedule, combining automatic monitoring tools and proper documentation.

1. Create a periodic inspection checklist

Weekly or monthly inspections are recommended depending on the area:

|

Inspection Item |

Action Description |

Recommended Frequency |

|

Filter pressure drop |

Read the value from a differential pressure gauge or sensor |

Weekly |

|

Filter color |

Check for gray or black color indicating dust buildup |

Monthly |

|

Air odor |

Smell the air directly at supply vents |

Every 1-2 weeks |

|

Unusual noise |

Listen for abnormal fan sounds (vibration, humming, etc.) |

Daily during operation |

Note: If the pressure drop exceeds the set limit or unusual odor/color is detected, replace the filter immediately without waiting for the scheduled date.

2. Install automatic differential pressure monitoring sensors

Use digital differential pressure sensors or analog gauges at each filtration stage.

Integrate alerts for:

- Exceeded pressure thresholds

- Reduced airflow caused by filter blockage

Recommended equipment:

- Magnehelic gauge (Dwyer): Accurate and durable pressure monitoring.

- Honeywell Delta P Sensor: Electronic sensor compatible with BMS/PLC.

- Remote LED display panel: Installed in control rooms for quick monitoring.

3. Maintain filter tracking and traceability records

Especially in pharmaceutical and electronics facilities, maintenance records must be fully documented.

|

Required Record |

Example Form |

|

Filter ID - Type - Installation location |

AHU tracking sheet |

|

Replacement history - Initial pressure reading |

HVAC maintenance log |

|

Periodic inspection results (DOP test, airflow test, etc.) |

HVAC validation report |

GMP note: All data should be stored in Excel with QR codes or integrated into a CMMS/BMS system for easy traceability and audit readiness.

7. Frequently Asked Questions

1. How often should a G4 filter be replaced?

The average replacement interval for G4 (pre-filters) is 1 to 3 months, depending on:

- Dust concentration in intake air

- HVAC operation frequency (continuous or by shift)

- Production environment (pharma plants usually replace earlier than cosmetics or food factories)

2. Can F8 filters be washed and reused?

No. F8 filters are compressed fine filters designed for single use. Washing them may:

- Deform the filter media

- Reduce dust retention efficiency

- Fail GMP or ISO 14644 compliance after reuse

Recommendation: Replace on schedule to maintain filtration efficiency and avoid cross-contamination risks.

3. Can all industries use the same replacement schedule?

No. Each industry requires a different cleanliness level. For example:

- Pharmaceutical: HEPA filters tested every 6 months.

- Food/Cosmetics: Typically use G4 + F8 filters with flexible replacement cycles.

- Electronics: Require continuous monitoring due to strict ISO 5-6 standards.

Tip: Build a customized replacement plan for each area and standard in your facility.

4. Can overdue filter replacement cause GMP audit failure?

Yes. In GMP (WHO/EU) audits, the HVAC section is carefully reviewed:

- Filters must have a clear replacement schedule and traceable records.

- Pressure drop, airflow, and DOP test results must meet the required standards.

If filters are not replaced on time or proper documentation is missing, the facility may be deemed non-compliant with GMP requirements.

8. Need Expert Help Replacing HVAC Filters Correctly?

Not sure when to replace your G4, F8, or HEPA filters?

Worried about GMP or ISO audit risks due to overdue filters?

Let the VCR Engineering Team assist you:

- Develop a customized replacement plan for each production area

- Recommend the right filters - compliant, efficient, and cost-effective

- Suggest suitable differential pressure sensors and monitoring gauges

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Diep VCR