HEPA (High Efficiency Particulate Air) filters are high-efficiency air filters that can retain up to 99.95% (H13) or 99.995% (H14) of ultra-fine dust particles of 0.3 μm in size – the most difficult type of dust to filter. In food factories, HEPA filters play a key role in maintaining a clean, standard environment and preventing cross-contamination

- 1. What is a HEPA filter?

- 2. Why is HEPA filtration mandatory in food factories?

- 3. Types of HEPA Filters for the Food Industry

- 4. Latest HEPA Filter Price List (Updated for 2025)

- 5. Factors Affecting HEPA Filter Prices

- 6. HEPA Filter Selection Guide by Area in Food Factories

- 7. HEPA Filter Warranty - Testing - Replacement Policy

- 8. Frequently Asked Questions (FAQ)

- 9. Contact for HEPA Filter Consultation & Quotation for Food Factories

1. What is a HEPA filter?

Operating Principle and Fine Particle Filtration

HEPA (High Efficiency Particulate Air) filters are high-performance air filters designed to retain at least 99.95% (H13) or 99.995% (H14) of dust particles sized 0.3 microns—the most difficult particle size to capture in the air.

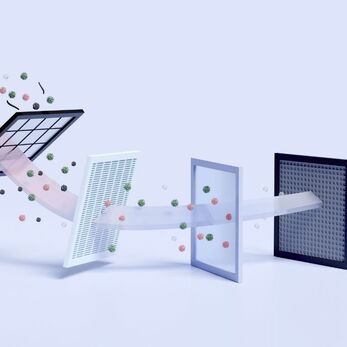

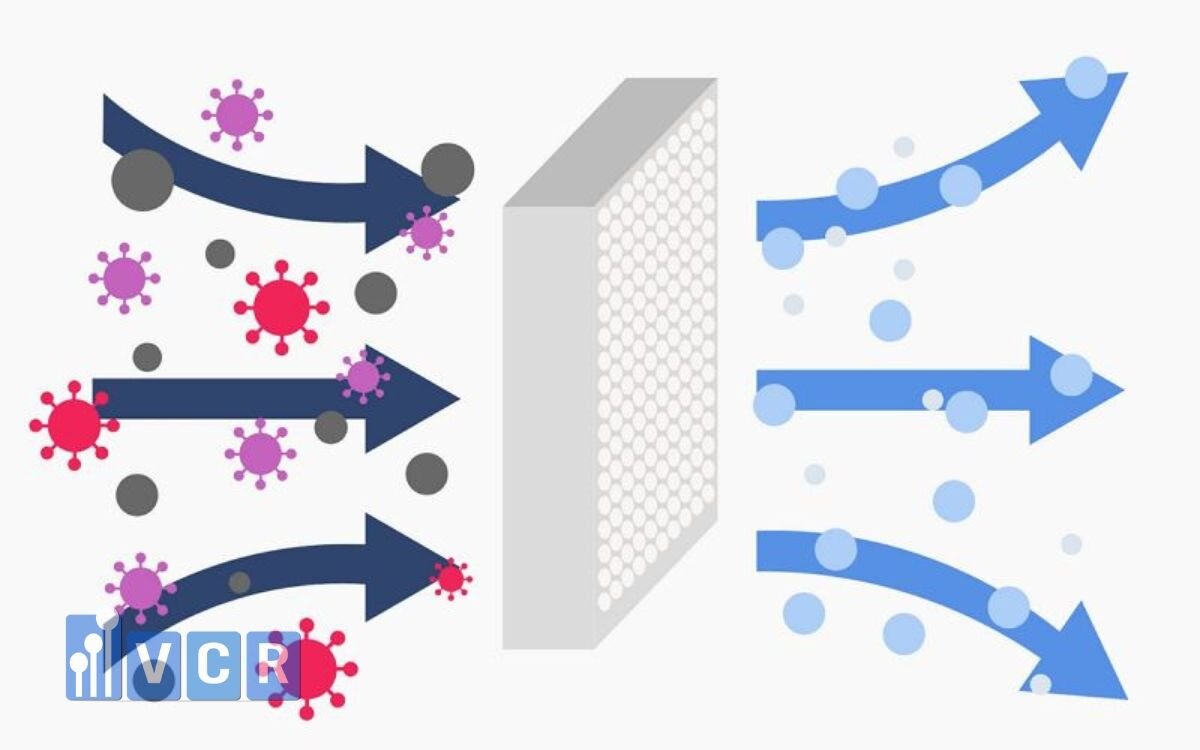

HEPA filters operate based on three main physical mechanisms:

- Inertial Impaction: Captures large particles (≥1 μm) by causing them to collide directly with the filter fibers.

- Diffusion (Brownian Motion): Very small particles (≤0.1 μm) move randomly and are trapped upon contact with fibers.

- Interception: Medium-sized particles follow the airflow, but are caught when they come into contact with filter fibers.

HEPA filters are most efficient at capturing particles sized 0.3 μm, referred to as the MPPS (Most Penetrating Particle Size). Therefore, this size is used as the standard for testing HEPA performance.

Difference between HEPA and ULPA

|

Criteria |

HEPA (H13-H14) |

ULPA (U15-U17) |

|

Filtration efficiency |

≥99.95% - 99.995% |

≥99.9995% - 99.999995% |

|

Effective particle size |

≥0.3 μm |

≥0.12 μm |

|

Fiber density |

Medium |

Very dense |

|

Pressure drop |

Lower |

Higher |

|

Application |

Food, pharmaceutical, standard electronics |

ISO 1-3 cleanrooms, semiconductors |

2. Why is HEPA filtration mandatory in food factories?

Compliance with Food Safety and Hygiene Standards

In the food industry, microbial cross-contamination, fine dust, or airborne impurities are risks that can spoil products, threaten consumer health, and lead to mass recalls.

These international standards require food factories to control air quality:

- HACCP (Hazard Analysis and Critical Control Points)

- ISO 22000 - Food safety management systems

- ISO 14644-1 - Cleanroom air cleanliness classifications (especially for filling and packing lines)

Installing HEPA filters in HVAC systems or equipment like FFUs (Fan Filter Units) is mandatory in critical zones such as filling, packaging, and blending to meet audit standards.

Role of HEPA Filters in Protecting Food Products

- Prevent ingress of fine dust, pollen, fibers, and microorganisms into the production line.

- Minimize cross-contamination between processing stages (especially for aromatic products, powdered milk, seafood).

- Create a stable production environment, prolong product shelf life, and meet export standards for strict markets like the EU, Japan, and the US.

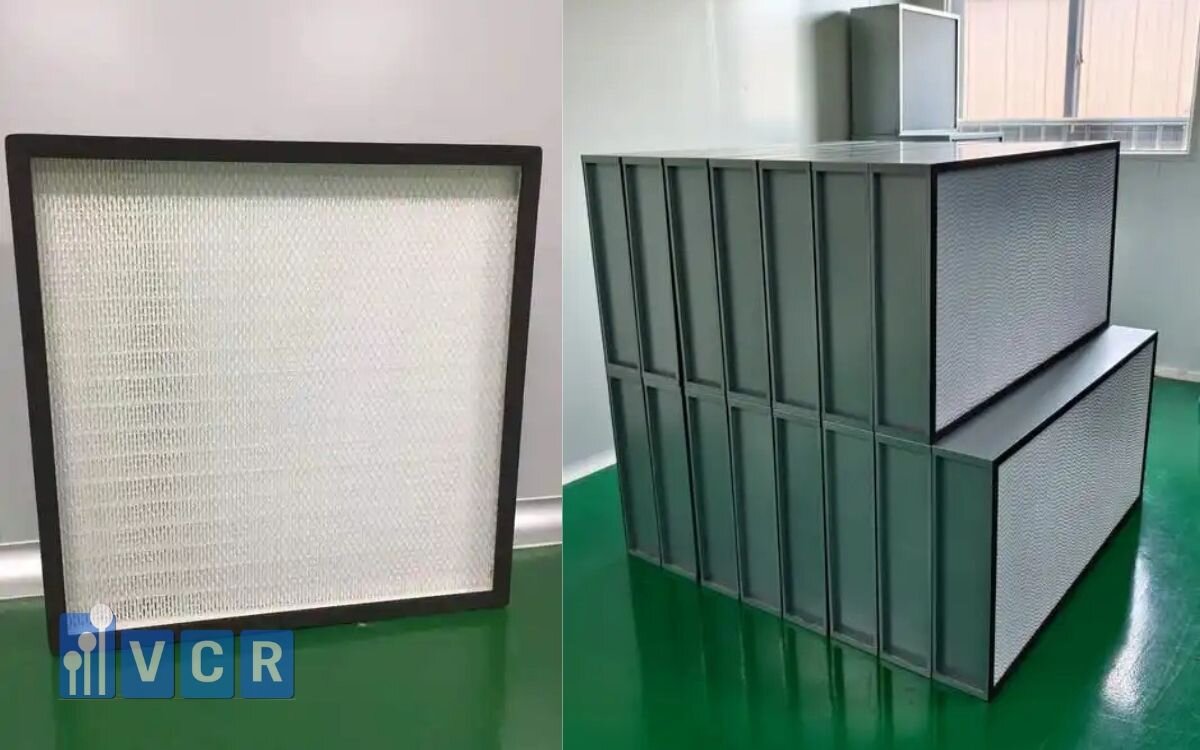

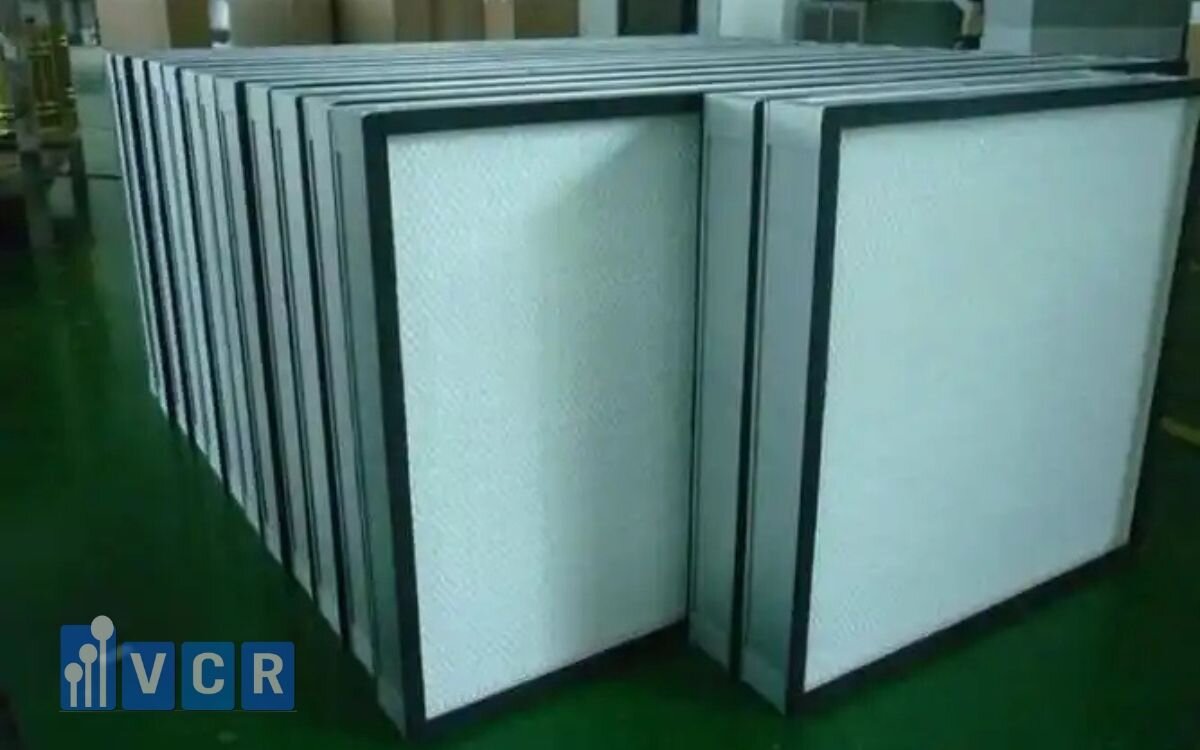

3. Types of HEPA Filters for the Food Industry

In food production environments, choosing the right HEPA filter impacts not only filtration efficiency but also compatibility with specific conditions such as temperature, humidity, oil, and microbial load in different zones.

Classification by Filtration Grade

|

Filtration Grade |

Filtration Efficiency |

Application |

|

H13 |

≥99.95% @ 0.3 µm |

Packaging area, pre-processing zones, clean storage |

|

H14 |

≥99.995% @ 0.3 µm |

Sterile filling, mixing rooms, ISO Class 7-8 areas |

Recommendation: For standard food factories, H13 is the typical choice. If producing sterile foods, fermented products, or powders that can easily disperse, H14 is more appropriate.

Classification by Frame Material

|

Frame Type |

Features |

Recommended Application |

|

Aluminum Frame |

Lightweight, mild corrosion-resistant |

Standard HVAC system installations |

|

Galvanized Steel Frame |

Durable, cost-effective |

Dry areas, not in direct contact with moisture |

|

Stainless Steel 304 |

Moisture-resistant, chemical-resistant |

Humid cleanrooms, seafood processing, dairy production |

Mini-Pleat vs. Deep-Pleat

- Mini-pleat HEPA: Compact pleats, space-saving, low pressure drop → Ideal for FFUs, ceiling-mounted applications.

- Deep-pleat HEPA: Larger filtration area, more durable → Suitable for centralized HVAC systems.

4. Latest HEPA Filter Price List (Updated for 2025)

Choosing the right HEPA filter for a food factory depends on more than just filtration grade—it also involves size, frame material, and design (mini-pleat, separator, gel seal, etc.). Below is the latest reference price list for popular HEPA filter models:

HEPA Filter Price Table by Technical Specifications

|

HEPA Filter Type |

Size (mm) |

Filtration Efficiency |

Frame Material |

Estimated Price (VND/unit) |

Application |

|

Mini-pleat H13 |

610×610×69 |

≥99.97% @ 0.3 µm |

Aluminum |

1,200,000 - 1,600,000 |

Airlock, corridors, ISO 7-8 cleanrooms |

|

Mini-pleat H14 |

610×610×69 |

≥99.995% |

Aluminum |

1,600,000 - 2,200,000 |

Weighing rooms, FFUs, HEPA filter boxes |

|

Gel Seal H14 |

610×610×90 |

≥99.995% |

Aluminum / Gel |

2,800,000 - 3,500,000 |

Sterile filling rooms, ISO 5 required zones |

|

Separator H14 |

610×610×150 |

≥99.995% |

Steel / Stainless |

2,200,000 - 3,000,000 |

AHU systems, air shower cabinets |

|

ULPA U15-U16 |

Custom sizes |

≥99.9995% |

Aluminum / Inox |

4,500,000 - 7,000,000 |

High-level sterile rooms, ISO 4-5 environments |

Important Notes:

- Prices above exclude VAT and shipping fees.

- Unit prices may vary depending on order quantity, technical specifications, or custom configurations.

- Please contact us directly to get an accurate quotation based on your actual dimensions, filtration requirements, and installation location.

5. Factors Affecting HEPA Filter Prices

The cost of a HEPA filter depends on much more than just its size or filtration grade. Various technical and operational factors can significantly affect pricing. Below are six key determinants:

1. Filtration Grade: H13 - H14 - ULPA

- H13: ≥99.95% @ 0.3 µm → Suitable for ISO 7-8 cleanrooms → Lower cost.

- H14: ≥99.995% @ 0.3 µm → Used in critical areas → Typically 20-30% more expensive.

- ULPA (U15-U16): ≥99.9995% → For sterile cleanrooms → Costs up to twice as much as standard HEPA.

2. Filter Design Type: Mini-pleat, Separator, or Gel Seal

|

Design Type |

Characteristics |

Cost |

|

Mini-pleat |

Compact, lightweight, low pressure drop |

Budget |

|

Separator |

Aluminum vanes, larger filtration area |

Mid-range |

|

Gel Seal |

Gel gasket for airtight sealing |

Premium |

3. Filter Frame Material

|

Frame Material |

Features |

Price Impact |

|

Aluminum |

Lightweight, anti-corrosive |

Common, affordable |

|

Painted/Galvanized Steel |

Durable, suitable for HVAC systems |

Medium cost |

|

Stainless Steel 304 |

Moisture & chemical resistant |

High cost, used in seafood/dairy environments |

4. Filter Size and Thickness

The larger and thicker the filter, the greater the surface area → the higher the cost.

Example: An H14 filter measuring 610×610×150 mm can cost 30-40% more than a 610×610×69 mm model of the same grade.

5. Filtration Performance & Testing Standards

- Filters that undergo PAO or DOP testing typically cost more due to strict quality control procedures.

- Filters certified to EN1822 or ISO 29463 standards are often more expensive than uncertified OEM models.

6. Brand & Country of Origin

- Vietnam-made filters: More affordable, customizable.

- Imported (EU, Japan, Korea): Higher cost but often come with full certifications and documentation.

6. HEPA Filter Selection Guide by Area in Food Factories

Not all areas in a food factory require the same type of HEPA filter. Choosing the right filtration grade, size, and frame material for each functional space helps optimize cost, comply with ISO and HACCP standards, and extend equipment lifespan.

1. Packaging Rooms - Corridors - Airlocks

- Goal: Prevent cross-contamination, control microbial dust, protect finished goods.

- Recommended Filter:

- Mini-pleat H13, 610×610×69 mm

- Aluminum or galvanized steel frame

- Benefits: Cost-effective, sufficient efficiency (≥99.97%), easy to replace.

2. Ingredient Weighing - Intermediate Mixing Rooms

- Goal: Reduce cross-contamination from backflow of fine particles during operation.

- Recommended Filter:

- Mini-pleat H14 or Separator H14

- Aluminum or stainless steel frame (depending on humidity)

- Additional Note: Install in FFU or HEPA filter box.

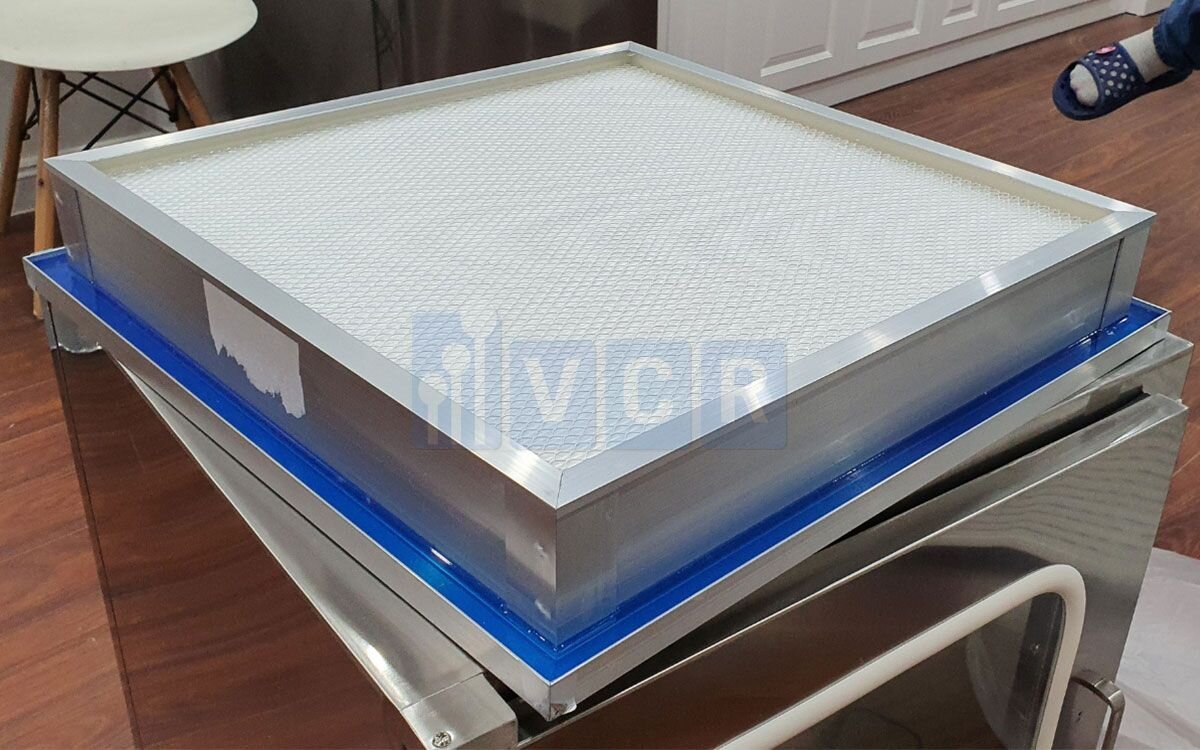

3. Sterile Filling - Aseptic Packaging - Clean Zones

- Goal: Meet ISO Class 5-6; prevent contamination of final product.

- Recommended Filter:

- Gel Seal H14 or ULPA U15

- Aluminum frame with airtight gel gasket

- Additional Requirements: Certified performance (PAO or DOP tested), ISO/EN compliance.

4. Cold Production Areas - Seafood, Beverages, Dairy Processing

- Environment: High humidity, risk of mold and microbial growth.

- Recommended Filter:

- Filtration grade: H14 or higher

- Stainless steel 304 frame (corrosion-resistant)

- Prefer filters with anti-humidity layers or antimicrobial treatment

7. HEPA Filter Warranty - Testing - Replacement Policy

Proper use of HEPA filters goes beyond installation. Clear warranty terms, regular performance testing, and timely replacement are essential to ensure air filtration systems run stably without efficiency loss over time.

Standard Warranty Policy

- Warranty period: 12 months from delivery date or 6 months from installation — whichever comes first.

- Warranty coverage:

- Manufacturing defects: torn filter media, loose glue, weak frame structure.

- Excludes: damages caused by shipping, improper installation, or unsuitable environments.

Reputable suppliers may offer extended warranties of 18-24 months for bulk or long-term contract orders.

Filtration Performance Testing (PAO/DOP Tests)

Mandatory for:

- Filters used in ISO Class 5-6 zones, sterile filling, or aseptic processing.

- Filters subject to third-party audits (e.g., HACCP, FDA, ISO).

Common testing methods:

- PAO test (Polyalphaolefin): On-site integrity test using oil-based tracer particles.

- DOP test: Similar method using Dioctyl Phthalate particles (less common in Vietnam).

Recommended frequency: Once per year or after each filter replacement cycle.

Recommended HEPA Filter Replacement Schedule

|

Filter Type |

Suggested Replacement Cycle |

Early Replacement Conditions |

|

Mini-pleat H13 - H14 |

12-18 months |

High pressure drop, reduced airflow |

|

Separator H14 |

18-24 months |

Failed inspection |

|

Gel Seal / ULPA |

12 months |

Sterile zones, strict audit requirements |

Note: In dusty, humid, or 24/7 production environments, inspect filters 6-9 months earlier.

Signs That a HEPA Filter Needs Replacement

- Differential pressure (ΔP) exceeds the design threshold.

- Unusual noise from air system or FFU.

- Airflow drops >15% compared to initial specs.

- Fails PAO/DOP test or shows leakage during routine inspection.

8. Frequently Asked Questions (FAQ)

1. Is H13 HEPA sufficient for food factories?

Yes, for most areas such as corridors, airlocks, and primary packaging rooms. H13 (≥99.95%) meets ISO 7-8 and HACCP standards. However, H14 or ULPA is recommended for sterile filling zones.

2. How often should HEPA filters be replaced?

It depends on usage:

- Standard H13/H14: Replace every 12-18 months.

- ULPA / Gel Seal: Replace every 12 months in sterile areas.

Regularly monitor pressure drop, airflow rate, and perform scheduled inspections to determine the optimal replacement time.

3. Can the same HEPA filter type be used throughout a food factory?

Not recommended. Different zones require different filtration standards, temperature resistance, and humidity protection.

- Airlocks → Use H13.

- Sterile filling → Use H14 with gel seal.

- Cold rooms → Require stainless steel frame filters.

Best practice: Choose filters based on room function (see Section 6).

4. Is PAO testing required for HEPA filters?

Yes, if filters are used in sterile environments, high-grade blending rooms, or for products exported to regulated markets. PAO testing ensures leak-free performance and verifies real filtration efficiency.

5. Can HEPA filters be reused?

No. HEPA filters are single-use products. Once saturated or contaminated, they lose filtration capacity. Attempting to clean or reuse them can lead to damage and cross-contamination risks.

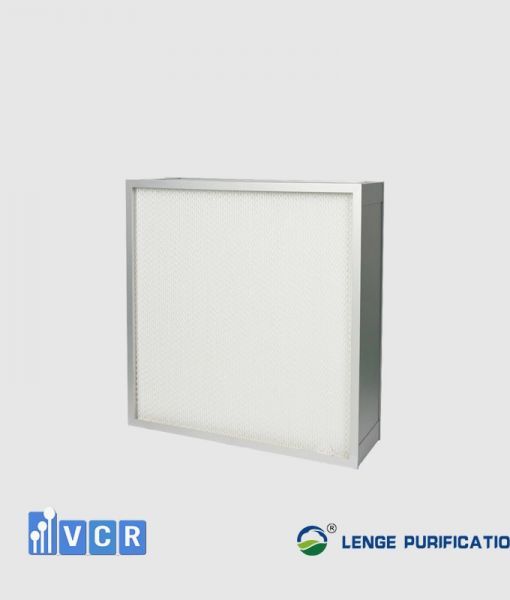

9. Contact for HEPA Filter Consultation & Quotation for Food Factories

Are you looking for an air filtration solution that meets HACCP, ISO 22000, and ISO 14644 standards for your food production facility?

Let the technical team at Vietnam Cleanroom Equipment (VCR) assist you from consultation - quotation - system design - to the supply of certified HEPA filters tailored to your needs.

Contact us now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Diep VCR