Clean air is a vital factor in the food, pharmaceutical, and cosmetics industries. The HACCP standard requires strict control of air contamination, and HACCP-compliant air filters are a solution that helps factories maintain a clean, safe environment and comply with international regulations.

1. A solution for the clean air challenge in an HACCP environment

In sensitive manufacturing sectors such as food processing, pharmaceuticals, and cosmetics, controlling microbial contamination, dust, and airborne impurities is essential. Invisible microorganisms in the air can lead to cross-contamination, spoil the product, or even pose health risks to consumers.

What is an Air Filter, and why is it needed in an HACCP environment?

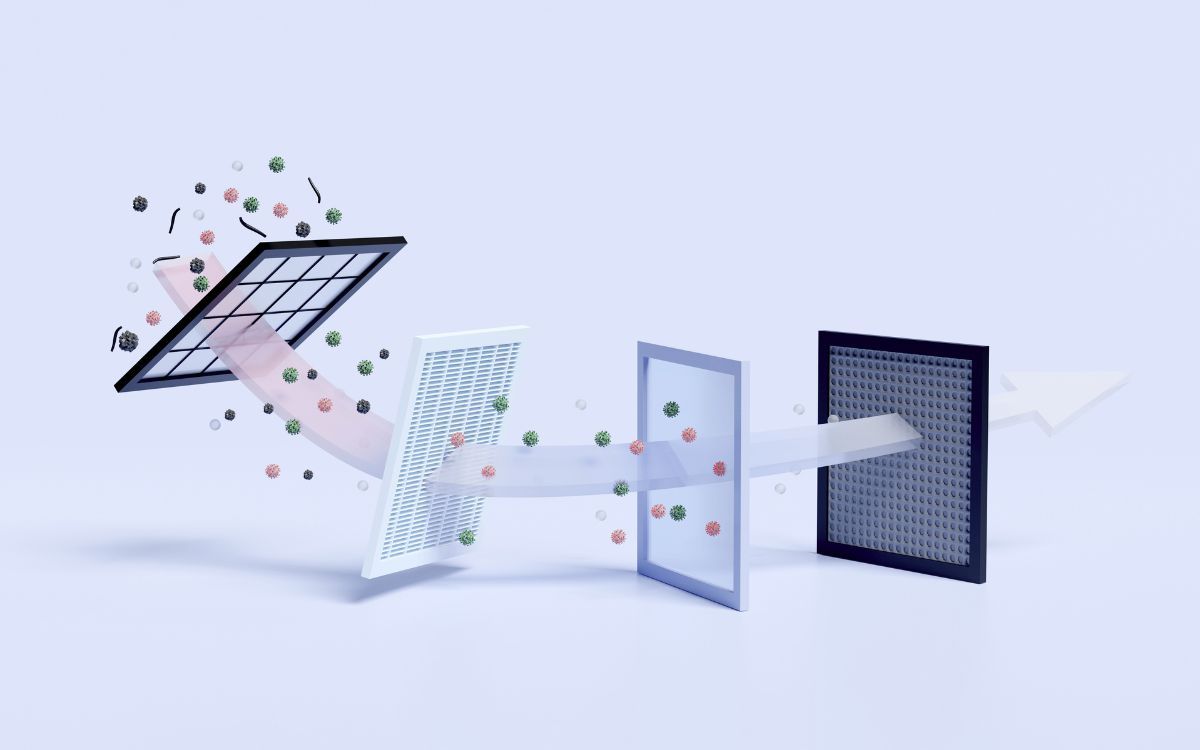

An air filter is a component in a factory’s HVAC or AHU system that removes dust, bacteria, and impurities from the air before it enters production zones. Depending on required cleanliness levels, the filter system may include:

-

Pre-filter: for coarse dust

-

Medium filter: for finer dust

-

HEPA/ULPA filter: for ultrafine particles and microorganisms

In an HACCP environment, the air filter’s roles include:

-

Preventing contamination at the intake

-

Maintaining stable air pressure and flow

-

Protecting finished products from invisible agents

Why must air filters adhere to HACCP standards?

Ordinary “clean air filters” often cannot meet the hygiene and safety demands of food or pharmaceutical production. A HACCP-standard air filter should:

-

Be made with materials that won’t shed secondary particles

-

Achieve high filtration efficiency (at least H13 per EN1822)

-

Be easy to inspect, clean, and replace

-

Have traceable quality certifications

Installing HACCP-compliant air filters not only helps with regulatory compliance but also builds trust with partners and consumers, reducing the risk of product recalls or regulatory nonconformity.

Read more: Latest price list of Heat-resistant HEPA filters used in Cosmetic factories

2. HACCP criteria in selecting air filters

HACCP (Hazard Analysis and Critical Control Points) is a food safety management system based on identifying hazards and controlling critical points. Air quality is a critical factor. Filter systems used in clean manufacturing must adhere to strict criteria to avoid becoming contamination sources.

Key evaluation criteria for HACCP air filters:

-

High filtration efficiency (HEPA, ULPA, etc.)

HEPA filters remove 99.97% of particles ≥ 0.3 μm; ULPA filters remove up to 99.999% of particles ≥ 0.12 μm. The higher the filtration class, the better it protects against microorganisms and fine dust. -

Antibacterial and antifungal resistance

The filter surface may be treated with antimicrobial agents or use materials to inhibit microbial growth, especially vital in food, dairy, or beverage production where humidity can foster microbes. -

Safe, non-emitting materials

Filters should not shed fibers or emit formaldehyde, VOCs, or reactive chemicals, to avoid becoming sources of contamination themselves. -

Ease of inspection, maintenance, traceability

Filters should be easy to remove, inspect, and replace without causing backflow contamination, and must be labeled with identification codes and come with CO/CQ documentation. This ensures compliance with HACCP audits.

Read more: Important differences in the production of HEPA Filters H13 and H14

3. VCR - A reputable supplier of HACCP-standard air filters

With over 10 years in Vietnam’s cleanroom industry, VCR is among the pioneers in providing equipment and environmental control solutions that meet international standards. VCR has supported numerous factories in food, pharmaceuticals, cosmetics, and electronics to build HVAC systems meeting GMP, HACCP, and ISO 14644 standards.

Product catalog that meets HACCP standard

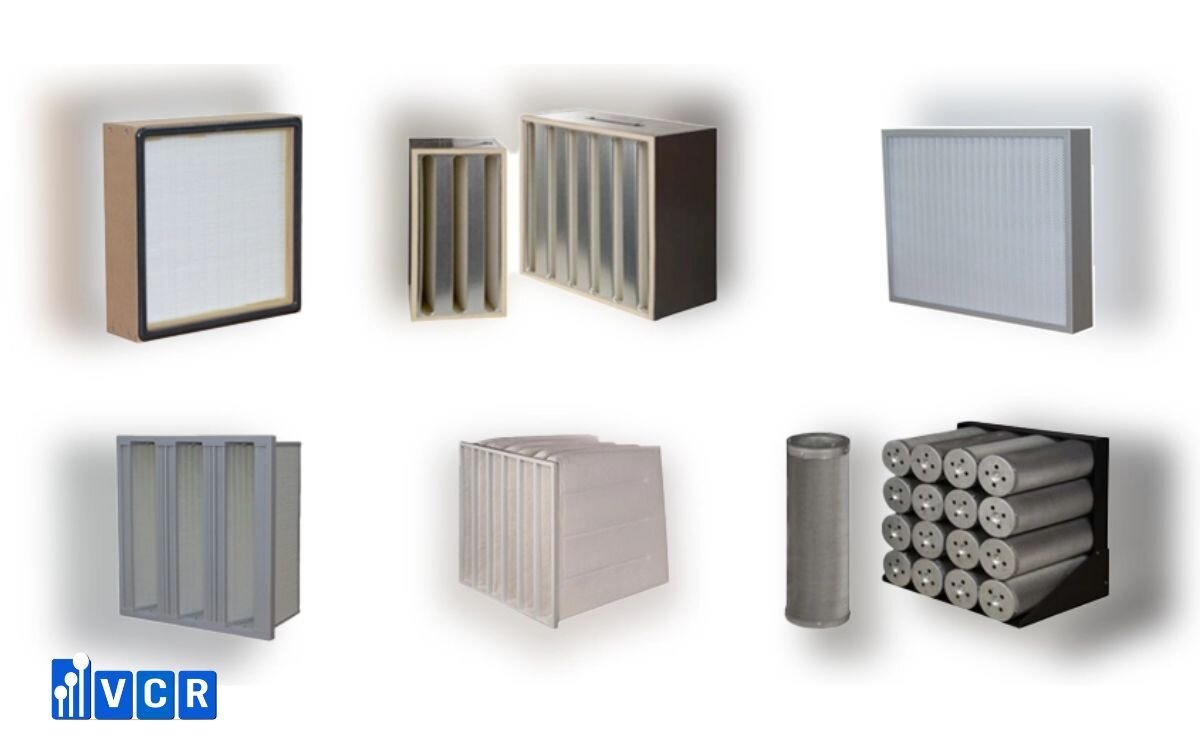

VCR offers a wide range of specialized air filters, tested to meet requirements in HACCP environments:

-

Pre-filter G3, G4 (coarse filtration)

-

Medium filters F5 - F9

-

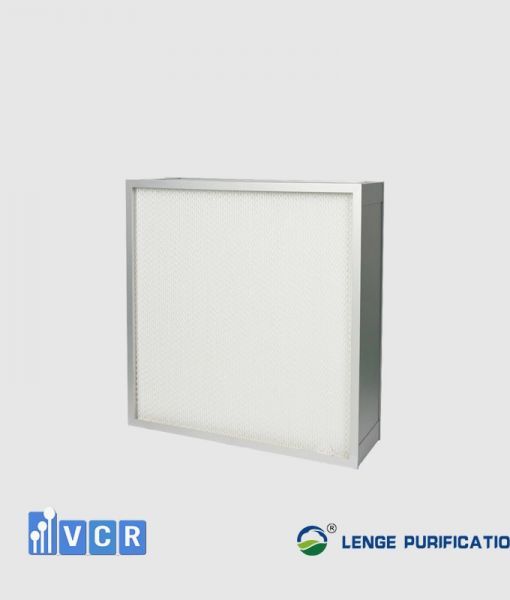

HEPA filters H13 - H14 for microbial and fine particulate removal in ISO cleanrooms

-

ULPA filters U15 - U17 for sterile or ultrapure processes

-

Specialized filters (antibacterial, odor control, gas filtration) depending on application

All products come with CO/CQ documentation and comply with filter performance, safe materials, and secondary particle emission criteria.

Strict quality testing process

Before reaching customers, each filter from VCR undergoes a rigorous validation process:

-

Performance testing using particle measurement devices

-

Leak testing (for HEPA/ULPA filters)

-

Cleanroom-grade packaging to limit microbial contamination

-

Barcode or QR code labeling for traceability

VCR also commits to post-sales technical support:

-

Advising on the correct filter class for each HACCP zone

-

Guidance on replacement and routine maintenance

-

On-site performance retesting

-

Technical reports suitable for GMP/HACCP audits

With a team of skilled engineers and a professional support system, VCR is a trusted partner for factories adopting HACCP standards.

Read more: Air Filter Supplier — Air Filter Meeting GMP Standard

4. Benefits of choosing the right HACCP-standard air filter supplier

Selecting a proper HACCP-compliant air filter supplier is not just about regulatory compliance — it is a long-term strategy to optimize operations, reduce risk, and enhance brand value.

-

Ensure product quality & adherence to international standards

HACCP-grade filters help control airborne contaminants, minimize microbial intrusion, and meet audit criteria under HACCP, GMP, and ISO 22000. -

Minimize cross-contamination & air pollution risks

Poor quality filters can allow microbial growth, particulate leakage, or pressure instability. Correct filters and expert guidance help maintain stable clean air systems over time. -

Boost brand reputation with certified cleanliness

Being certified for HACCP production environments helps access strict markets (EU, Japan, Korea), earn consumer trust, and gain favorable ESG (environmental, social, governance) standing. -

Optimize maintenance & replacement costs

Choosing substandard filters or unexperienced suppliers may lead to system damage, short filter lifespan, and extra audit costs. Working with a specialist like VCR ensures correct sizing, expected filter life, and a clear maintenance schedule.

Read more: Latest price list of HEPA filters used in electronics factories

5. Frequently Asked Questions (FAQ)

Q: How are HACCP-standard air filters different from regular filters?

A: HACCP-qualified air filters have higher efficiency (HEPA/ULPA), safe materials, no emission, and come with full CO/CQ documentation. Regular filters used in residential HVAC systems are not designed to meet the stringent demands of food or pharmaceutical production.

Q: Which industries must use HACCP-compliant air filters?

A: Industries such as food processing, dairy production, pharmaceuticals, and cosmetics must use HACCP filters to ensure safety and pass regulatory audits.

Q: How often should air filters be replaced?

A: It depends on the filter grade and environment:

-

Pre-filters: every 3-6 months

-

Medium filters: every 6-9 months

-

HEPA filters: every 12-18 months

Differential pressure checks should guide the actual replacement timing.

Q: Does VCR provide filter performance testing?

A: Yes. VCR offers performance testing, leak tests, CO/CQ certification, and technical consultation in line with periodic HACCP/GMP audits.

If you need GMP‑compliant Air Filters for pharmaceutical, food, or cosmetic factories, VCR is a reliable partner offering COA, DOP testing, clear origin, free consultation, fast delivery, and on‑site inspection support.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Dat VCR