The F7 air filter is a crucial link in clean-room filtration systems, acting as the intermediate filter between G4 and HEPA. With an efficiency of 80-90 % according to EN 779 and ePM1 70-80 % according to ISO 16890, F7 helps remove fine particles of 0.4 µm, protects downstream equipment and maintains air quality in compliance with GMP – ISO 14644.

- What is an F7 Air Filter?

- Position of the F7 Filter in Clean Room Air Filtration Systems

- Why the F7 Filter Is Important in Clean Rooms

- Applications of the F7 Filter in Specific Industries

- How to Choose a Suitable F7 Filter

- Solutions from VCR - Specialist Supplier of F7 Air Filters for Clean Rooms

- Frequently Asked Questions (FAQ) About F7 Filters

What is an F7 Air Filter?

Definition according to standards EN 779 and ISO 16890

The F7 air filter is a medium filter in air-filtration systems, designed to remove fine dust particles of size from 0.4 µm upward. Under the two common standards:

-

EN 779:2012 (Europe - now superseded by ISO 16890): F7 belongs to the fine-filter group, with a filtration efficiency of about 80-90 % for particles of 0.4 µm (MPPS - Most Penetrating Particle Size).

-

ISO 16890 (current standard): The F7 filter corresponds to a filter with efficiency of 65-85 % for PM1 fine dust, classified as ePM1 70-80 %.

F7 filters are often used to protect downstream HEPA filters and improve indoor air quality in environments requiring medium to high cleanliness levels.

Construction of F7 filters

A typical F7 air filter includes:

-

Filter media: made from synthetic polyester fiber or microfiber, with high dust-holding capacity and even airflow distribution.

-

Pleated design: V or M shaped pleats that increase surface area and reduce pressure drop.

-

Frame: usually made of galvanized steel, aluminum or rigid plastic, ensuring durability and stable shape in operation.

-

Protective mesh: some models include a protective grid layer to hold the filter media in place, preventing tearing or deformation.

This structure allows the F7 filter to operate reliably over long durations and be easily installed in AHU (Air Handling Unit), FCU (Fan Coil Unit) or filter box systems.

Distinguishing F7 from other filter classes

| Filter class | Efficiency (EN 779) | Particle size | Position in system | Application |

|---|---|---|---|---|

| G4 (coarse) | ~90% for large dust | >10 µm | Primary filtration | Large dust, lint, insects |

| F5-F7 (fine) | F5 ~40-60%, F7 ~80-90% | 1-5 µm | Intermediate filtration | Protects HEPA, elevates air quality |

| F8-F9 | >90% | <1 µm | Mid-to-high grade | Clean rooms Class 10000-1000 |

| H13-H14 (HEPA) | >99.95% | ≥0.3 µm | Final filtration | High grade clean rooms, microbiology |

Thus, F7 plays a “middle” role between coarse and absolute filtration, helping reduce load on the HEPA filter and ensuring the overall system efficiency.

Read more: HACCP-Standard Air Filter Supplier - A Solution for Clean Air

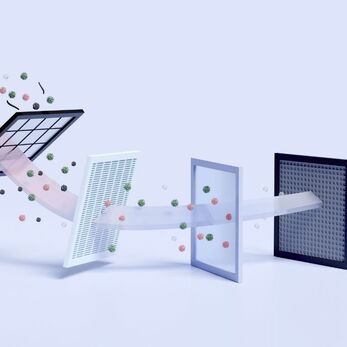

Position of the F7 Filter in Clean Room Air Filtration Systems

Typical installation locations in AHU/FCU systems

In air-handling and treatment systems, the F7 filter is typically installed:

-

In the intermediate filter bank within the AHU, between primary (coarse) and fine or HEPA filtration.

-

In a standalone intermediate filter box before air enters end-devices or clean rooms.

-

At the inlet of an FCU in areas requiring high air quality such as laboratories, semiconductor production, pharmaceuticals and microbiology.

Placement ensures air is processed step-by-step, reducing load on high-grade upstream filters. The F7 filter belongs to the medium-filtration stage:

-

After coarse filtration (G4), which removes large dust and lint.

-

Then the F7 filter removes finer dust particles that the coarse filter cannot catch, which otherwise would stress the HEPA filter.

Absent the F7 filter in this chain, the HEPA could become overloaded quickly, reducing its lifespan and increasing replacement cost.

Why the F7 Filter Is Important in Clean Rooms

Filtration efficiency: removes 80-90% of 0.4 µm particles

The F7 filter is engineered to handle fine particles from 0.4 µm upward, which may include:

-

Airborne bacteria and moulds.

-

Allergenic or pollutant-carrying particles.

-

Dust particles carrying electrical charges impacting electronics.

According to EN 779:2012, F7 can achieve average filtration efficiency of 80-90% for the MPPS (Most Penetrating Particle Size) range. This prevents most hazardous particles before the air reaches the costlier HEPA filters.

Protects HEPA filters from premature clogging → extends lifespan

HEPA filters are expensive and require periodic replacement. Without the intermediate F7 filter, fine dust would quickly accumulate in the HEPA core, causing:

-

Rapid rise in pressure differential → increased fan power demand.

-

Reduced filtration efficiency → compromised clean-room classification.

-

Shorter service life or earlier replacement of HEPA → higher cost.

Hence, the F7 filter acts as an efficient defense line, helping extend HEPA lifespan by 30-50%, and reducing maintenance frequency and total operating cost.

Stabilizes airflow pressure, saves operating cost

In a multi-stage filtration chain, differential pressure increases as air flows through layers, making the fan work harder. The F7 filter, with optimized design (deep pleats, large surface area) helps:

-

Distribute airflow evenly, preventing dust accumulation hot-spots.

-

Maintain stable system pressure.

-

Reduce energy consumption of AHU/FCU fans.

-

Contribute to long-term operational cost savings.

Ensures clean-room standard compliance across industries

Each production sector sets different cleanliness levels (according to ISO 14644-1 or GMP), yet all require a multi-stage filtration system where F7 is central:

-

Pharmaceutical industry: removes fine dust and microbes ahead of HEPA to maintain Class 10,000 or Class 1,000 clean rooms.

-

Food & beverage: prevents bacteria, mould spores from air entering packaging lines.

-

Electronics / semiconductor: filters ultra-fine dust causing electrostatic issues, damaging microcircuits.

Without the F7 filter, these industries would struggle to maintain stable production conditions and meet clean-room audit standards.

Read more: Air Filter Supplier — Air Filter Meeting GMP Standard

Applications of the F7 Filter in Specific Industries

The F7 air filter is indispensable in many industries that require clean, stable production environments and controlled fine particle levels. Depending on each industry’s characteristics, the F7 filter is integrated into air-filtration systems to meet different technical standards and clean-room regulations.

Pharmaceutical industry

-

Purpose: The F7 filter is used to remove fine dust and microorganisms larger than 0.4 µm before the air enters a HEPA filter.

-

Role: Ensures that air supplied to production areas, packaging zones or raw-material storage is free from harmful contaminants or microbial ingress.

-

Filtering requirement: Compliance with EN ISO 14644-1 Class 7 or better, under GMP-WHO guidelines.

Electronics / Semiconductor industry

-

Purpose: The F7 filter traps dust particles capable of carrying electrostatic charge, which could damage micro-circuits, boards or cause defects during chip manufacturing.

-

Role: Protects circuit boards and devices in environments that require strict electrostatic control.

-

Filtering requirement: Typically clean rooms of Class 1,000 - 10,000, depending on production stage and product type.

Food & Beverage industry

-

Purpose: Filters fine dust, bacteria and mould spores in air before it enters processing or packaging areas.

-

Role: Maintains production environments without cross-contamination, preventing spoilage or food safety violations.

-

Filtering requirement: Clean room levels Class 10,000 or better, especially in dry-packaging lines.

Cosmetics industry

-

Purpose: Ensures that air used in production, filling and packaging areas contains no fine dust or microbes.

-

Role: Maintains stability in production processes, preserving product structure, purity and safety (e.g., creams, serums, perfumes).

-

Filtering requirement: Commonly Class 1,000 - 10,000 clean rooms, depending on product type.

Summary Table

| Industry | Purpose of Use | Air-filtration Requirement |

|---|---|---|

| Pharmaceuticals | Remove microbes and fine dust before HEPA | EN ISO 14644-1 Class 7 or better |

| Electronics | Capture electrostatic-carrying dust | Class 1,000-10,000 |

| Food & Beverage | Filter bacteria & mould spores in air | Class 10,000 or better |

| Cosmetics | Ensure clean air in filling/packaging zones | Class 1,000-10,000 |

Read more: Latest price list of HEPA filters used in medical clean rooms

How to Choose a Suitable F7 Filter

Choosing the right F7 air filter not only guarantees filtration efficiency but also optimizes operating and maintenance costs for clean-room systems. Here are the technical factors to consider:

Airflow capacity (Airflow, m³/h):

-

Each F7 filter has a maximum rated airflow (typically 1000-3600 m³/h, depending on model).

-

You should calculate the total system airflow and choose the number and size of filters accordingly to avoid overload, pressure drop or reduced efficiency.

Filter frame size:

-

Common standard sizes: 592×592×292 mm, 287×592×292 mm …

-

The size must fit the filter housing or fixed frame in your AHU, FCU or intermediate filter box.

Filter media material:

-

Prefer synthetic fiber or microfiber, with good dust-holding capability and minimal collapse during continuous operations.

-

The media must be moisture-resistant and mold-resistant, especially important in food and pharmaceutical environments.

Check initial pressure differential (ΔP):

-

The pressure drop between filter inlet and outlet is a key indicator of condition.

-

Initial ΔP for an F7 filter typically ranges 80-150 Pa.

-

When ΔP exceeds 250-300 Pa, cleaning (if possible) or replacement should be considered to prevent flow reduction and increased energy consumption.

-

Tip: install a differential pressure gauge at the filter location for continuous monitoring.

Replacement frequency depends on environmental conditions and operating hours:

There is no one-size-fits-all replacement cycle. It depends on:

-

Seasonal or outdoor air pollution levels.

-

Daily operating hours (8h, 16h, or 24/7).

-

Clean-room grade requirements of each industry (GMP, ISO class).

Recommendation for replacement intervals:

-

Standard clean environment, 8-10 h/day → 5-6 months.

-

Dusty or humid environment, 12-16 h/day → 3-4 months.

-

Highly critical environment (GMP), 24/7 operation → 2-3 months.

Adhering to these cycles helps maintain stable filtration efficiency and ensures the clean-room remains compliant.

Read more: Latest price list of HEPA filters used in food factories

Solutions from VCR - Specialist Supplier of F7 Air Filters for Clean Rooms

As a specialist in clean-room equipment, VCR is high-quality F7 air filters supplier that meet engineering requirements for HVAC, AHU, FCU systems in major industries in Vietnam.

Compliance to EN 779 / ISO 16890

-

The F7 filters supplied by VCR are tested for filtration efficiency according to EN 779:2012 and ISO 16890 — ensuring removal of up to 80-90% of fine dust PM1/PM2.5.

-

Filter media are carefully selected, with strong frames, moisture resistance, suitable for Vietnamese climate and production conditions.

-

Complete CO/CQ documents and technical certificates accompany each shipment.

Technical consultation tailored to each industry

-

VCR’s engineering team surveys the actual site and provides advice on selecting an appropriate F7 filter based on:

-

The industry (pharmaceutical, food, electronics, cosmetics…)

-

The required cleanliness class (ISO Class, GMP, HACCP…)

-

The current HVAC system structure.

-

-

They support designing multi-stage air-filtration solutions, optimizing efficiency and long-term operating cost.

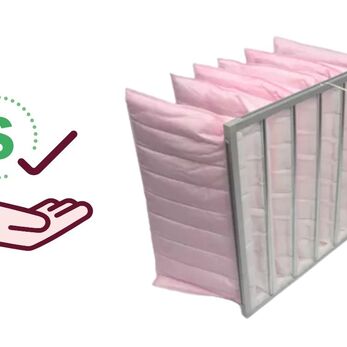

Stock & fast delivery nationwide

-

VCR maintains large inventory of F7 filters in Hanoi and Ho Chi Minh City, with a variety of sizes and frame types (paper, aluminum, metal).

-

Commitment to 24-48-hour delivery for domestic orders.

-

Supports custom packaging and provides installation accessories on request.

Full service: replacement & maintenance

-

Besides supplying products, VCR offers full maintenance and periodic replacement services for air filters to help customers:

-

Ensure continuous system operation without interruption.

-

Reduce load on in-house technical teams.

-

Easily track filter replacement cycles via an automated technical-management system.

-

-

Special packages exist for companies with multiple production zones or clean rooms across different provinces.

Read more: Latest price list of HEPA filter used in cosmetic factory

Frequently Asked Questions (FAQ) About F7 Filters

Does the F7 filter remove bacteria?

Not directly — F7 is not designed to kill or capture bacteria like a HEPA filter does. However, it can retain dust particles, liquid droplets or contaminants larger than 0.4 µm, which are often carriers of bacteria in the air. Thus, it indirectly helps reduce microbial contamination in a clean-room environment.

How often should the F7 filter be changed?

On average, every 3-6 months — depending on:

-

Incoming outdoor air contamination level.

-

Hours of operation per day (8h, 16h or 24/7).

-

Industry’s clean-room grade requirement (GMP, ISO class).

Also, if the pressure drop across the filter exceeds 250 Pa, replacement should be done to maintain airflow and filtration efficiency.

Can the F7 filter be washed and reused?

Not recommended. While some types may allow preliminary cleaning with compressed air, washing or reusing can:

-

Damage the filter media or pleat structure.

-

Significantly reduce original filtration efficiency.

-

Fail to guarantee cleanliness for sensitive environments (pharma, electronics).

It’s best to replace with a new filter to ensure clean-room standards.

Can the F7 filter replace HEPA?

No. The F7 filter achieves mid-level filtration efficiency of around 80-90% for fine dust, while HEPA (H13, H14) delivers ≥99.95% efficiency for particles ≥0.3 µm. F7 is used to protect HEPA, not substitute its final filtration purpose.

In summary: The F7 air filter plays an essential intermediate role in clean-room air-filtration chains — not only efficiently removing fine particles but also protecting downstream HEPA filters, lowering operating costs and ensuring clean-room classification for each industry. If you are looking for an optimal filtration solution for a factory, production line or clean room compliant with GMP or ISO 14644-1, consider contacting VCR.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Dat VCR