Air Filter is the “lungs” of the electronics clean room – helping to remove ultrafine dust, ions and harmful microorganisms from semiconductor components. VCR supplies HEPA and ULPA air filters with efficiency ≥ 99.99% @ 0.3 μm, ensuring the environment meets ISO 14644 standard, and remains stable and durable throughout all production lines.

- 1. What is an Air Filter? Why Is It Important in the Electronics Industry Clean Room?

- 2. Common Types of Air Filters in Electronic Clean Rooms

- 3. Criteria for Choosing a Supplier of Air Filters for Electronics Clean Rooms

- 4. VCR – A Reliable Supplier of Clean-Room Air Filters for the Electronics Industry

- 5. Frequently Asked Questions (FAQ)

1. What is an Air Filter? Why Is It Important in the Electronics Industry Clean Room?

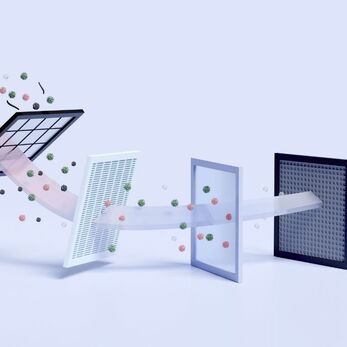

An air filter is a device used to remove dust, microorganisms, textile fibers, volatile chemicals and ultrafine particles present in the air. In clean-room systems, especially in the electronics industry where extremely high cleanliness is required, air filters play an essential role in ensuring the production environment meets standards.

Filtering ultrafine dust – protecting electronic components from contamination

Microcircuits and semiconductor components in the electronics industry are extremely sensitive to fine dust, ions, static electricity and chemical gases. Without thorough filtration, such contaminants can:

-

Cause short circuits, combustion, surface corrosion of components.

-

Distort electrical characteristics, reduce product performance.

-

Increase defect rate, making inspection and rework more costly.

Therefore, air filters such as HEPA (High Efficiency Particulate Air) or ULPA (Ultra Low Penetration Air) are used to filter up to 99.99% of particles ≥ 0.3 micron, helping maintain an environment that meets ISO 14644-1 or FS209E standards.

Clean air quality has a direct impact on manufacturing performance and defect rate:

-

Yield Rate: Clean air helps reduce the number of defective products due to contamination during manufacturing.

-

Maintenance time – machine performance: Equipment in a clean environment lasts longer and is less prone to failure due to dust or contamination.

-

Manufacturing cost: Reduced cost in inspection, rework, maintenance and warranty.

Thus, investing in the right high-quality air filter is not only a technical requirement, but also an economic solution to optimize production processes in electronics factories.

Read more: Latest price list of HEPA filters used in electronics factories

2. Common Types of Air Filters in Electronic Clean Rooms

In clean-room HVAC systems, especially in electronic component manufacturing, choosing the correct type of clean room air filter matched to the cleanliness class is key to controlling environmental quality. Each filter type plays a different role in the multi-stage filtration chain — from rough to fine — in order to ensure optimal filtration efficiency and long service life for the entire system.

Filter types and their main applications:

-

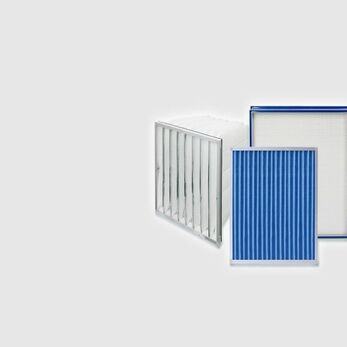

Pre-filter (rough filter): Classification G2-G4 — Captures large dust particles, textile fibres, pollen; protects downstream fine filters.

-

Medium filter: Classification M5-M6 — Filters fine dust, enhances the effectiveness and lifespan of the HEPA filter; placed in the middle of the system.

-

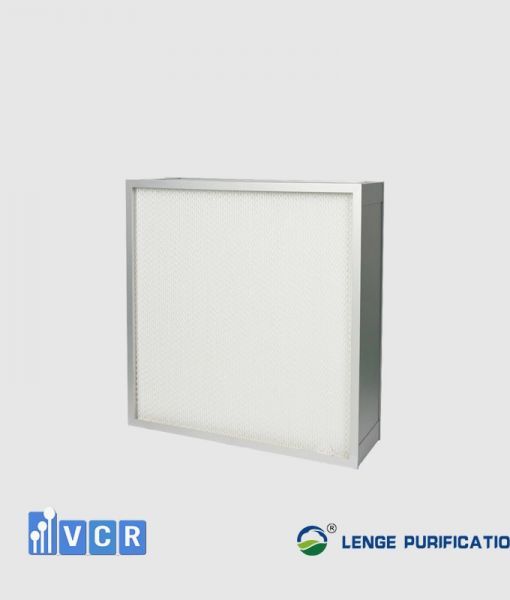

HEPA filter: Classification H13-H14 — Filters ≥ 99.97% of particles ≥ 0.3 micron; used in most electronics clean rooms.

-

ULPA filter: Classification U15 and above — Filters up to ≥ 99.9995% of particles ≥ 0.12 micron; used for ultra-sensitive cleanrooms (class 1–10).

Role of each stage in an electronics clean room:

-

The pre-filter is the first line of defence, capturing coarse particles and extending the lifespan of downstream filters.

-

The medium filter sits between pre-filter and HEPA, helping to block fine dust and enable the HEPA to operate more stably.

-

The HEPA filter is the heart of the clean-room air filtration system, ensuring the room meets ISO Class 5–7 depending on production needs.

-

The ULPA filter is used in extremely sensitive areas such as semiconductor chip printing, which require nearly absolute particle-free environments.

Combining the correct sequence of filter stages helps the system operate stably, save energy and reduce replacement costs. At the same time, this is also a metric to evaluate the design and installation capability of the filtration solution provider.

Read more: Important differences in the production of HEPA Filters H13 and H14

3. Criteria for Choosing a Supplier of Air Filters for Electronics Clean Rooms

Selecting the right air filter supplier doesn’t just affect the air-quality in the clean room but also determines the long-term stability and effectiveness of the entire production line. Here are important criteria to consider when choosing an air-filter supplier for an electronics plant:

Filtration efficiency verified in practice

-

Prefer suppliers whose products carry international certifications such as EN 1822 or testing by independent laboratories.

-

Important technical specifications should be transparent: filtration efficiency by grade (H13, H14…), initial pressure drop (initial resistance), dust-holding capacity.

-

It’s advisable to request an inspection report accompanying each batch to ensure quality.

Durability and filter lifespan

-

Filter material: choose ultra-fine fiberglass fibres, antibacterial, moisture-resistant.

-

Filter frame: preferably stainless steel 304 or extruded aluminium with high durability and corrosion resistance.

-

The filter core structure must be uniform, without pleat misalignment which reduces performance after usage.

In-depth technical consultation

-

The supplier needs to understand clearly the clean-room class requirement according to ISO 14644-1, and thereby advise on the correct filter type.

-

Must be capable of assisting in air flow design, differential pressure calculation, deciding installation position to optimise performance.

-

Provide technical drawings, catalogs and detailed installation guides.

After-sales service and warranty

-

Have a support policy for replacement, leak-check, cleaning and scheduled filter change.

-

Provide kit for pressure-drop monitoring, or on-site testing service to evaluate operating efficiency.

-

Clear warranty policy, minimum 6–12 months depending on filter type.

Supply capacity and delivery schedule

-

Choose a supplier with inventory of standard size filters ready to meet urgent replacement needs.

-

Must be capable of custom-sizing filters for specialized HVAC systems.

-

Ensure on-time delivery, especially for urgent projects in operating factories.

Read more: Latest price list of Heat-resistant HEPA filters used in Cosmetic factories

4. VCR – A Reliable Supplier of Clean-Room Air Filters for the Electronics Industry

In the electronics industry — where every ultrafine dust particle can severely impact product quality — choosing the right air-filter supplier is a matter of survival. VCR is proud to be the partner of hundreds of electronics factories in Vietnam, providing internationally-standard air-filtration solutions optimised for each clean-room class.

Over 10 years of specialised experience in the clean-room field

VCR has a team of engineers and specialists experienced in designing and operating clean-room systems for the electronics industry. We do not just supply products but provide comprehensive consulting to ensure the air-filtration system reaches highest efficiency.

Offering a wide variety of air-filters – meeting all demands

-

HEPA filters (H13, H14): filtration efficiency ≥ 99.97% @ 0.3 micron.

-

ULPA filters (U15 – U17): for clean-rooms class 1–10, extremely high filtration level.

-

Separator filters: robust structure, large airflow, used for AHUs and terminal boxes.

Additionally, VCR also accepts manufacturing of filters to custom dimension according to specific HVAC systems.

Clear verification of filtration performance – meets international standards

All air filters supplied by VCR undergo rigorous inspection:

-

Conforms to EN 1822 standards.

-

Provide full test reports: leak test, airflow test, efficiency test for each batch.

-

On-site re-testing support available if requested by customers.

On-site technical service – periodic maintenance

Not only supplying equipment, VCR also provides full suite of technical services:

-

Measure filter differential pressure – signalling timely replacement.

-

Perform leak testing using PAO/DOP methods.

-

Advise on upgrading air-filtration systems when existing systems don’t meet standards.

Read more: Air Filter Supplier — Air Filter Meeting GMP Standard

5. Frequently Asked Questions (FAQ)

Q: How often should the air filter be replaced?

A: The replacement interval depends on many factors such as air-flow rate, dust concentration in the environment, and the system’s configuration. Under standard operating conditions, HEPA filters typically need replacement every 6–12 months to maintain stable filtration efficiency. In dustier environments or continuous operation, this interval may be shorter. Monitoring the filter’s pressure drop is the most effective way to determine when replacement is needed.

Q: Can one HEPA filter be used for all electronics factories?

A: No. HEPA filters come in many grades (H13, H14…), and cannot be universally used for all clean-rooms. Each factory will have its own cleanliness class requirement according to ISO 14644-1 or FS209E, depending on the type of product manufactured (micro-chips, displays, camera modules, etc.). Therefore selecting the correct filter grade and configuration is mandatory to ensure product quality and optimise operational cost.

Q: Does VCR accept manufacturing filters in custom sizes?

A: Yes. VCR provides air filter manufacturing services to meet technical requirements, including:

-

Custom size according to actual installation space.

-

Option of frame material (stainless steel, aluminium, electro-painted steel…).

-

Option of filter media, pleat depth, protective layer.

This solution is particularly useful for factories with specially designed HVAC systems or needing replacement of older filters in non-standard sizes.

Do not let ultrafine dust, bacteria and air contaminants affect the quality of your electronics products. With practical experience and internationally-standard products, VCR commits to bringing you an air-filtration solution that is effective, stable and cost-efficient in the long term.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Dat VCR