In the cosmetics industry, high temperature areas such as autoclaves, hot filling or sterilization require heat-resistant HEPA filters. With the ability to withstand 250°C - 350°C, the filter ensures a clean environment that meets GMP - ISO 22716. So how much does a heat-resistant HEPA filter cost in a cosmetics factory?

- 1. Quick Introduction to High-Temperature HEPA Filters in the Cosmetics Industry

- 2. Key Factors Affecting the Price of High-Temperature HEPA Filters

- 3. Latest Price List for High-Temperature HEPA Filters for Cosmetic Manufacturing Facilities

- 4. Choosing the Right HEPA Filter for Each Area in a Cosmetics Manufacturing Plant

- 5. FAQ - Frequently Asked Questions

- 6. Need a Quote for High-Temperature HEPA Filters? VCR Is Ready to Assist!

1. Quick Introduction to High-Temperature HEPA Filters in the Cosmetics Industry

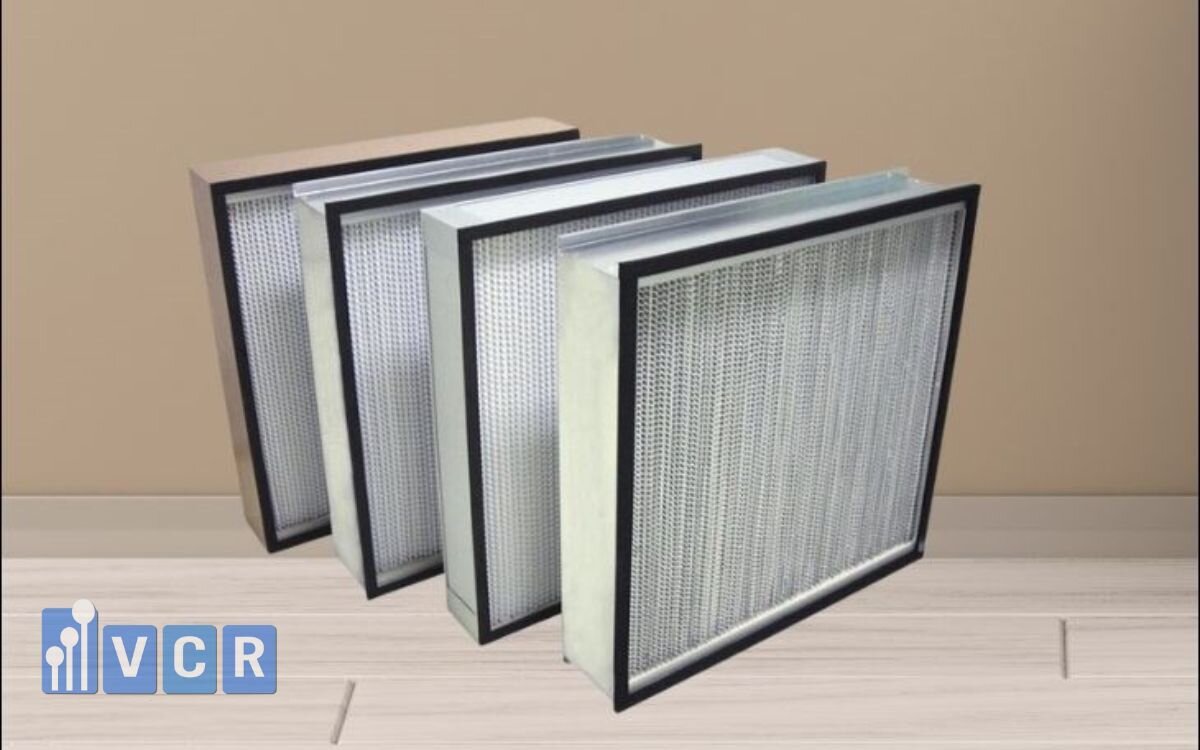

In the cosmetics manufacturing industry, maintaining a cleanroom environment that meets strict standards is crucial for ensuring product quality and safety. HEPA (High Efficiency Particulate Air) filters play a central role in cleanroom HVAC systems, capable of removing up to 99.97% of particles ≥0.3 microns — including bacteria, mold spores, and fine dust that could cause cross-contamination.

However, in high-temperature areas such as:

- Sterilization chambers

- Hot filling zones

- Heat-based disinfection rooms standard HEPA filters are often inadequate. This is where high-temperature HEPA filters prove essential:

- Capable of withstanding temperatures up to 250°C - 350°C for extended periods

- Made from materials that resist deformation and prevent particle shedding under thermal stress

- Ensure consistent cleanliness levels even during sterilization, drying, or cooling processes

Using the right type of high-temperature HEPA filter for each area not only helps the facility comply with GMP and ISO 22716 standards but also reduces the risk of microbial contamination and extends equipment lifespan.

2. Key Factors Affecting the Price of High-Temperature HEPA Filters

The price of high-temperature HEPA filters varies depending on several technical factors. Understanding these will help cosmetic manufacturers select the most suitable filter based on performance needs and budget.

1. Filter Materials

- Filter media: Typically made of ultra-fine fiberglass, offering high dust-holding capacity and excellent heat resistance.

- Filter frame: Made of 304 or 316 stainless steel for corrosion resistance and durability under high heat. Stainless steel frames cost more than aluminum or galvanized options.

2. Temperature Resistance

Each HEPA filter type is designed for a specific maximum operating temperature:

- 120°C: Suitable for low-heat or drying zones

- 250°C: Ideal for hot filling or rapid sterilization areas

- 350°C: Required for continuous operation in autoclave or high-heat sterilization rooms

→ Higher temperature ratings require more advanced materials and testing, resulting in increased costs.

3. Size and Airflow Capacity

HEPA filters come in various standard sizes, such as 610x610x150 mm or 915x610x292 mm.

→ Larger filters allow for greater airflow, require more media and framing, and thus come at a higher price point.

4. Filtration Standards (Efficiency)

Common certification standards include:

- EN1822: H13 (99.95%), H14 (99.995%)

- ISO 29463: Equivalent to ISO 35 H and ISO 45 H

→ The higher the filtration grade, the more stringent the manufacturing and testing requirements — leading to higher cost.

3. Latest Price List for High-Temperature HEPA Filters for Cosmetic Manufacturing Facilities

To assist cosmetics manufacturers in selecting the appropriate filtration equipment, below is the most updated price list for high-temperature HEPA filters provided by VCR. All products are individually tested and certified according to EN1822 standards, making them suitable for use in GMP and ISO 22716-compliant environments.

Reference Price List - High-Temperature HEPA Filters

|

Product Code |

Filtration Grade |

Dimensions (mm) |

Airflow (CMH) |

Max Temp |

Frame |

Price (VND) |

|

VCR-H13-120 |

H13 |

610x610x150 |

1000 |

120°C |

Inox 304 |

2,900,000 |

|

VCR-H14-250 |

H14 |

610x610x292 |

1200 |

250°C |

Inox 304 |

4,500,000 |

|

VCR-H14-350 |

H14 |

915x610x292 |

1800 |

350°C |

Inox 316 |

6,200,000 |

|

VCR-CUSTOM |

H13/H14 |

Custom sizes |

As requested |

120°C-350°C |

Inox 304/316 |

Contact us |

All prices include individual performance test certificates and cleanroom-grade packaging.

4. Choosing the Right HEPA Filter for Each Area in a Cosmetics Manufacturing Plant

Not all areas within a cosmetics production facility require the same HEPA filter specifications. Choosing the correct high-temperature HEPA filter improves filtration performance, reduces costs, and ensures compliance with GMP and ISO 22716 standards across each production phase.

Packaging Area - H13 Filter, 120°C Resistance

- Dry environment with minimal heat exposure

- Primary goal: Remove dust, fibers, airborne microbes

- Recommendation: H13 filter, standard size, heat resistance up to 120°C

- Suggested Model: VCR-H13-120 - ideal for packaging and sealing areas

Hot Filling & Capping Area - H14 Filter, High Airflow

- Presence of steam or short bursts of elevated temperatures

- Requires high cleanliness to avoid microbial contamination

- Demands higher airflow to maintain positive pressure

- Recommendation: H14 filter, heat resistance up to 250°C, larger size (915x610x292 mm)

- Suggested Models: VCR-H14-250 or VCR-H14-350 depending on HVAC capacity

Sterilization - Autoclave Zone - H14 Filter, 250-350°C Resistance

- Continuous high-temperature operation

- Risk of material degradation if incorrect filter is used

- Needs excellent durability and long-term filtration stability

- Recommendation: H14 filter, Inox 316 frame, resistance up to 350°C

- Suggested Model: VCR-H14-350 - suitable for autoclaves and high-heat exhaust systems

Filter selection should always be based on actual operating temperatures and airflow requirements. If unsure, we recommend sending room layout drawings or specifications for accurate technical consultation from VCR’s engineering team.

5. FAQ - Frequently Asked Questions

1. How is a high-temperature HEPA filter different from a standard HEPA filter?

→ High-temperature HEPA filters are specifically designed to operate in elevated temperature environments (120°C - 350°C), whereas standard HEPA filters typically withstand up to only ~80°C.

- The filter media is made of ultra-fine heat-resistant fiberglass.

- The frame is usually constructed from 304 or 316 stainless steel, instead of aluminum or galvanized steel.

→ As a result, these filters remain structurally stable and do not release secondary particles under continuous thermal stress.

2. How often should high-temperature HEPA filters be replaced in a cosmetics plant?

→ Replacement frequency depends on the operating environment and system usage:

- Low-dust, stable conditions: approximately every 12 months

- High humidity, hot zones, or continuous operation: every 6-9 months

To ensure safety and performance, we recommend regularly monitoring pressure drop or airflow decline as indicators for replacement.

3. Are individual test certificates available for each filter?

→ Yes. All high-temperature HEPA filters supplied by VCR come with:

- Individual test certificates verifying filtration efficiency per EN1822 or ISO 29463

- Unique serial number labels for traceability

- Factory test reports, with optional on-site testing upon request

6. Need a Quote for High-Temperature HEPA Filters? VCR Is Ready to Assist!

Choosing the right high-temperature HEPA filter is not only essential for meeting strict standards like GMP and ISO 22716, but also critical for maximizing filtration efficiency, reducing contamination risk, and lowering long-term maintenance costs.

If you are:

- Looking for a quick quotation for HEPA filters

- Needing technical advice on which filter suits your sterilization, filling, or packaging areas

- Requiring custom filter sizes tailored to your HVAC system design

Don’t hesitate — contact the VCR technical team today:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Diep VCR