HEPA (High Efficiency Particulate Air) filter is a specialized air filter that can retain ≥99.95% of ultra-fine dust particles from 0.3 microns, ensuring a clean environment in production. Investing properly in HEPA filter not only helps control fine dust, microorganisms, prevent cross-contamination but also meets GMP - ISO 22716 standards.

- 1. What is a HEPA Filter?

- 2. Common Types of HEPA Filters Used in the Cosmetic Industry

- 3. Latest HEPA Filter Price List (Reference)

- 4. Factors Affecting HEPA Filter Pricing in Cosmetic Plants

- 5. Recommended HEPA Filter Selection for Cosmetic Manufacturing

- 6. Frequently Asked Questions

- 7. Contact Us for the Latest HEPA Filter Prices

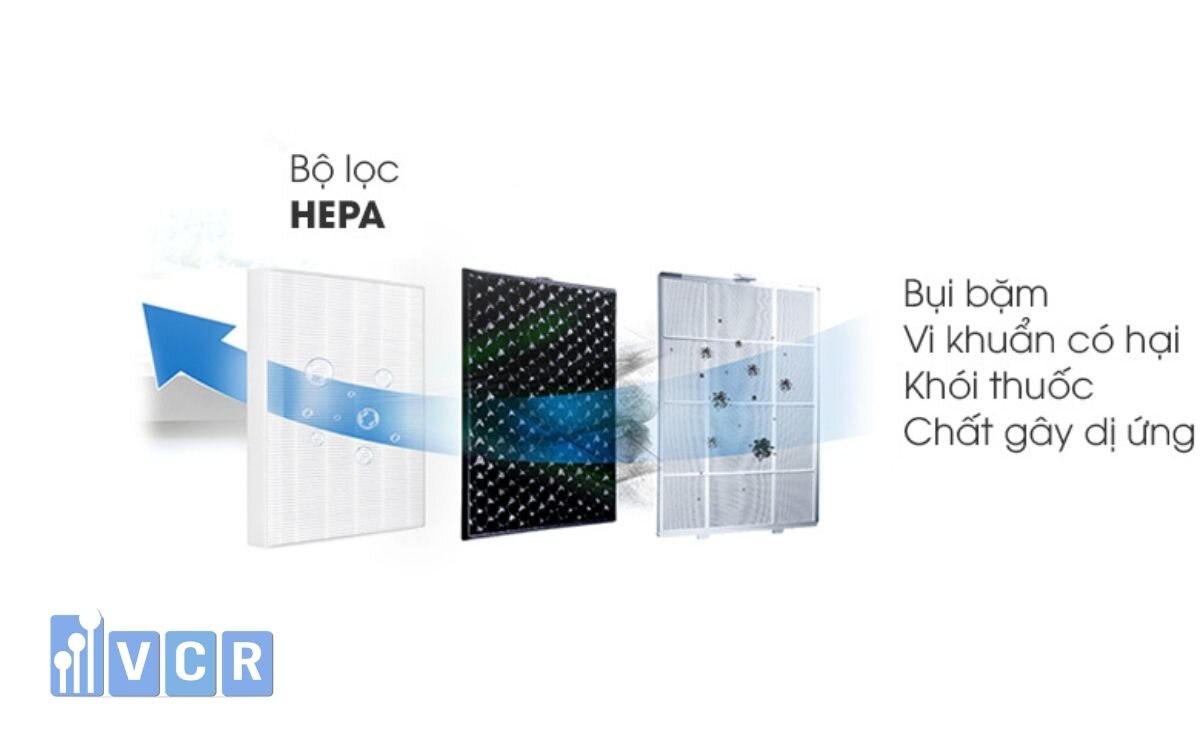

1. What is a HEPA Filter?

HEPA (High Efficiency Particulate Air) filter is an air filtration device capable of capturing at least 99.95% of particles ≥ 0.3 microns in size. This type of filter is mandatory in industries that require clean environments — especially in cosmetics manufacturing.

Why are HEPA filters important in cosmetic factories?

In cosmetic production — particularly in areas such as filling, packaging, and airlock zones — controlling fine dust, airborne microorganisms, and contaminants is critical to:

- Ensure consistent product quality

- Comply with GMP - ISO 22716 standards

- Prevent cross-contamination and environmental pollution

HEPA filters help maintain cleanroom classifications ranging from ISO 8 to ISO 5, depending on each zone’s requirements.

Common HEPA filter installation points in cosmetic facilities:

- Filling & Packaging Rooms: Ensures clean air is directly in contact with products

- Changing Rooms (Airlocks): Reduces dust and microbes from personnel before entering clean areas

- Cleanroom Ceilings: Installed inside FFUs or HEPA boxes to deliver vertical laminar flow

- HVAC Ducts: Used as terminal filters before air is released into critical zones

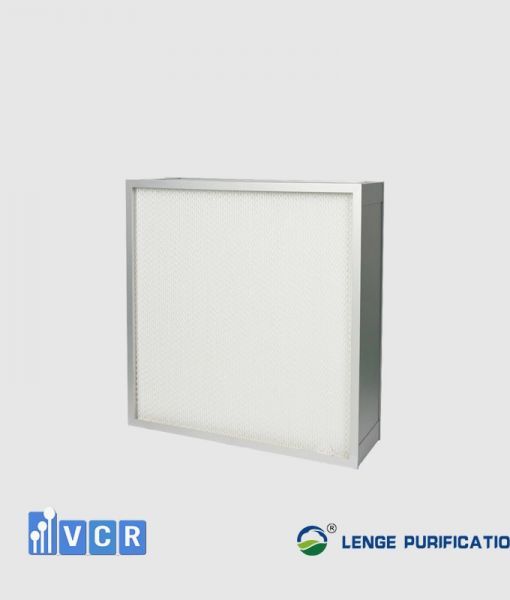

2. Common Types of HEPA Filters Used in the Cosmetic Industry

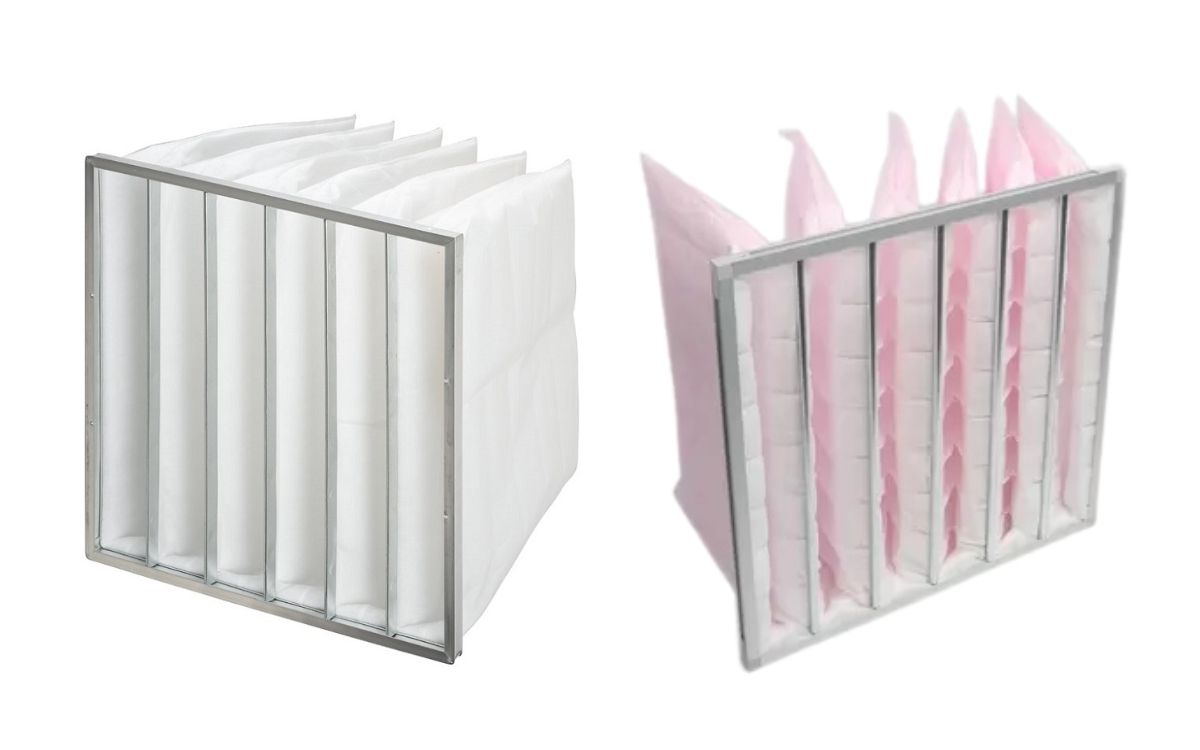

Each production area in a cosmetic factory may require different air cleanliness levels and HVAC setups. Therefore, HEPA filters come in a variety of types with different specifications, tailored to meet specific applications.

Classification of HEPA Filters by Structure & Application:

|

HEPA Filter Type |

Typical Size |

Filtration Efficiency |

Typical Application |

Key Advantages |

|

Standard HEPA H13 |

610x610x69 mm |

≥ 99.95% @ 0.3µm |

Ceiling-mounted in ISO 8 cleanrooms |

Cost-effective, easy replacement |

|

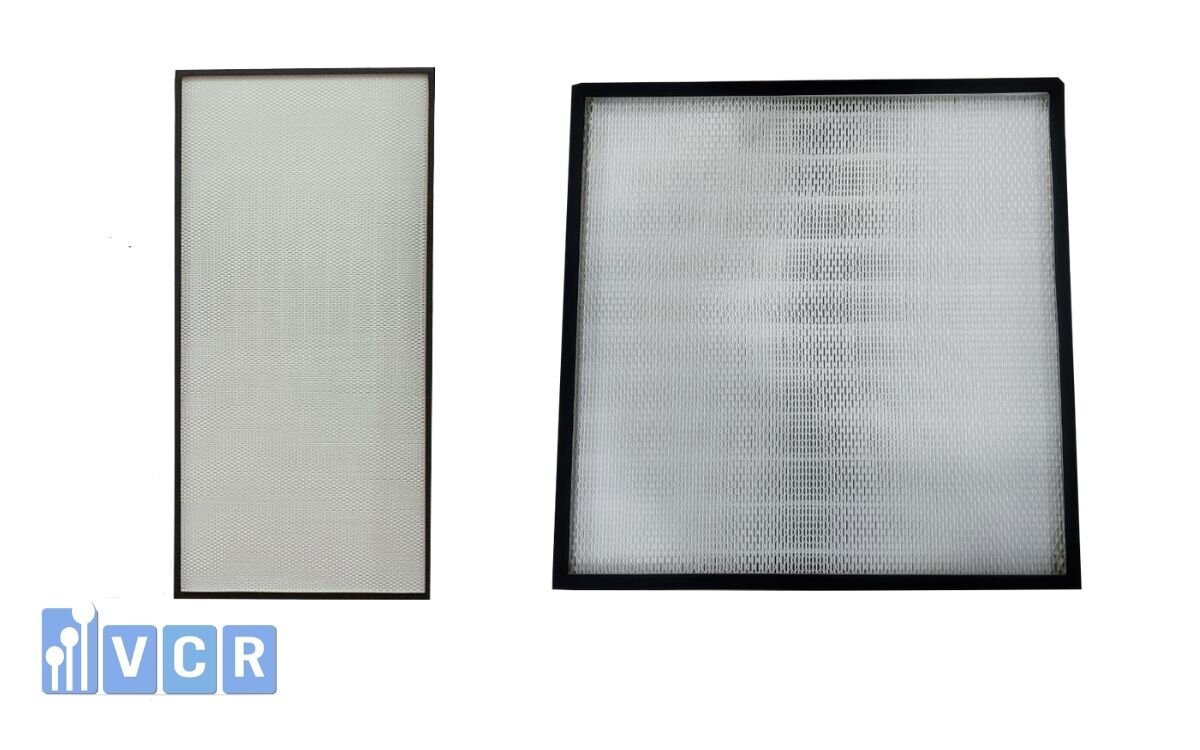

Mini Pleat HEPA |

Customizable |

≥ 99.99% |

Compact areas, laminar flow hoods |

Slim, lightweight, space-saving |

|

HEPA Box (Terminal Unit) |

Built-in box casing |

≥ 99.99% |

HVAC terminals, packaging zones |

Easy to install, plug-and-play design |

|

Gel Seal HEPA Filter |

610x610x69 mm |

≥ 99.995% (H14) |

Aseptic zones, filling rooms |

High airtightness, GMP-compliant |

Filter Selection Tips by Application Zone:

- Packaging Room: Use HEPA Box H14 with integrated diffuser

- Filling / Dosing Areas: Choose gel-sealed HEPA filters for maximum leak protection

- Changing Room / Airlock: Standard H13 HEPA filters are sufficient

- Benches & Small Devices: Mini Pleat HEPA filters offer space-saving efficiency

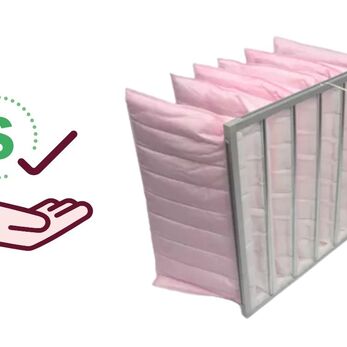

3. Latest HEPA Filter Price List (Reference)

The price of HEPA filters used in cosmetic manufacturing facilities depends on various factors such as filter type, filtration grade, dimensions, frame design, airtightness requirements, and order quantity. Below is a reference price list for commonly used HEPA filters in 2025:

Reference Price Table:

|

Product Name |

Size (mm) |

Grade |

Efficiency |

Price (VND) |

Remarks |

|

Standard HEPA Filter H13 |

610x610x69 |

H13 |

≥ 99.95% @ 0.3µm |

~1,200,000 |

Common in ISO 8 cleanrooms |

|

HEPA Filter H14 |

610x610x69 |

H14 |

≥ 99.995% |

~1,650,000 |

For zones requiring high cleanliness |

|

Mini Pleat HEPA |

305x610x50 |

H13/H14 |

≥ 99.99% |

~850,000 |

Suitable for laminar hoods, compact spaces |

|

HEPA Box H14 (with housing) |

610x610 + box |

H14 |

≥ 99.99% |

~2,200,000 |

Easy to install, comes with aluminum housing |

|

Gel-Seal HEPA Filter |

610x610x69 |

H14 |

≥ 99.995% |

~2,600,000 |

High airtightness, ideal for GMP compliance |

Note: Prices may vary based on quantity, technical specifications, frame material (aluminum or stainless steel), and order time.

4. Factors Affecting HEPA Filter Pricing in Cosmetic Plants

HEPA filter prices are not fixed — they vary depending on technical specifications and specific project needs. Understanding the cost drivers helps manufacturers select the right filter while optimizing budget.

Key Factors Influencing HEPA Filter Prices:

1. Required Cleanroom Classification (ISO 7, ISO 8...)

- Cleanrooms classified ISO 7 or higher generally require high-grade H14 or premium H13 filters

- Higher cleanliness levels demand higher efficiency → increased filter costs

2. Frame Material & Construction

- Aluminum Frame: Cost-effective, easy to manufacture, widely used

- Stainless Steel 304 Frame: Durable, corrosion-resistant, more expensive

- Gel-Seal Filters: Designed for airtight sealing → higher production cost

- HEPA Box Units: Include housing, air duct connection, and air diffusers → higher total price than panel filters

3. Standards & Certification (GMP - ISO 22716)

- Cosmetic factories following GMP or ISO 22716 often require filters with full testing reports (EN1822, DOP test)

- Stricter validation = higher product quality = higher price

4. Order Volume (Project vs. Individual Orders)

- Bulk orders for entire factories receive better pricing and often include:

- Free technical consultation

- Discounted delivery and performance testing

5. Brand and Country of Origin

- Domestic products (Vietnam): Competitive pricing, flexible sizing, fast delivery

- Imported products (Korea, EU, China): More stable performance and variety, but usually higher in cost and longer lead times

Pro Tip:

For changing rooms or airlocks, a standard H13 filter with an aluminum frame is sufficient. For critical areas like filling and packaging, choose H14 filters with gel seal or certified HEPA Box units to meet compliance requirements.

5. Recommended HEPA Filter Selection for Cosmetic Manufacturing

Choosing the right HEPA filter is crucial not only for maintaining air quality but also for optimizing costs and ensuring compliance with GMP - ISO 22716 standards. Below are filter selection suggestions based on different functional areas within a cosmetic factory:

Final Packaging Room

- Recommendation: Use H14 filter or HEPA Box

- Reason: This is the final area where products are exposed; air must be ultra-clean to prevent cross-contamination

- Tip: HEPA Box H14 with integrated air diffuser is easy to install and can include sampling ports if needed

Filling Room

- Recommendation: Prioritize gel-seal H14 filters

- Reason: High airtightness is required to prevent airborne contaminants from reaching raw ingredients

- Tip: Combine gel-sealed filters with FFU (Fan Filter Unit) or positive pressure filter boxes for maximum efficiency

Changing Room / Airlock

- Recommendation: Use standard H13 filters

- Reason: These areas serve to prevent contamination from personnel and do not require high-level filtration

- Tip: Ceiling-mounted filters or FFU-attached filters are cost-effective

Factories with strict GMP compliance

- Recommendation: Use filters that have leak tests and EN1822 certification

- Reason: Meets equipment validation requirements during GMP audits

- Tip: Choose suppliers that offer on-site or factory testing, and provide complete documentation (CO, CQ, test reports)

Note: Never choose HEPA filters based on price alone — always consider the required cleanliness level, specific applications, and ease of maintenance.

6. Frequently Asked Questions

1: How often should HEPA filters be replaced in a cosmetic factory?

On average, every 6 to 12 months, depending on usage intensity, cleanliness level, and installation zone. For critical areas like filling or packaging, monitor pressure drop and replace earlier if needed.

2: Are gel-seal HEPA filters required for all areas?

Not necessarily. Gel-seal HEPA filters are intended for high-containment zones like filling and packaging. Supporting zones like changing rooms or airlocks only require standard H13 filters.

3: Does VCR offer HEPA filter performance testing on-site?

Yes. VCR provides HEPA filter testing according to EN1822, including pressure drop measurements and official test reports. Testing can be done on-site or at VCR's facility.

4: Can I order custom-sized HEPA filters?

Absolutely. VCR manufactures custom HEPA filters based on your specifications — including size, frame type (aluminum or stainless steel), filtration grade (H13-H14), gel seal options, or HEPA Box format to suit existing HVAC systems.

7. Contact Us for the Latest HEPA Filter Prices

Are you looking for the right HEPA filter for your cosmetic factory? Need a detailed quotation or consultation to meet GMP - ISO 22716 standards?

Let VCR support your project from A to Z:

- Transparent pricing with tailored solutions for each cleanliness level

- EN1822 filter performance testing (at factory or on-site)

- Custom filter fabrication based on size and technical requirements

- Fast delivery & full technical support on installation

Request a quote today:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Diep VCR