Air Filter is an essential air purification device in cleanroom HVAC systems, especially in pharmaceutical, food, and cosmetic manufacturing plants. Choosing an Air Filter supplier that meets GMP standards is a critical factor in ensuring a safe production environment, passing inspections, and avoiding cross‑contamination risks.

- 1. Role of Air Filters in GMP‑Compliant Plants

- 3. Risks of Choosing the Wrong Air Filter Supplier

- 4. VCR — A Specialized Supplier of GMP‑Standard Air Filters

- 5. Table: Classification of Air Filters by Industry Application

- 6. How to Inspect and Maintain Air Filters According to GMP

- 7. Frequently Asked Questions About GMP‑Compliant Air Filters

1. Role of Air Filters in GMP‑Compliant Plants

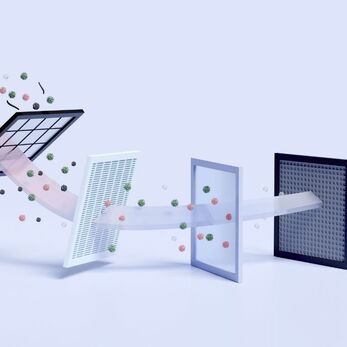

Air Filters (air filtration units) are indispensable in HVAC systems for cleanrooms. They help remove fine dust, bacteria, suspended particles, and other airborne contaminants that may cause cross‑contamination. In pharmaceutical, cosmetic, and food factories—where environmental control is strict—Air Filters form the first line of defense in protecting production quality.

How do Air Filters work?

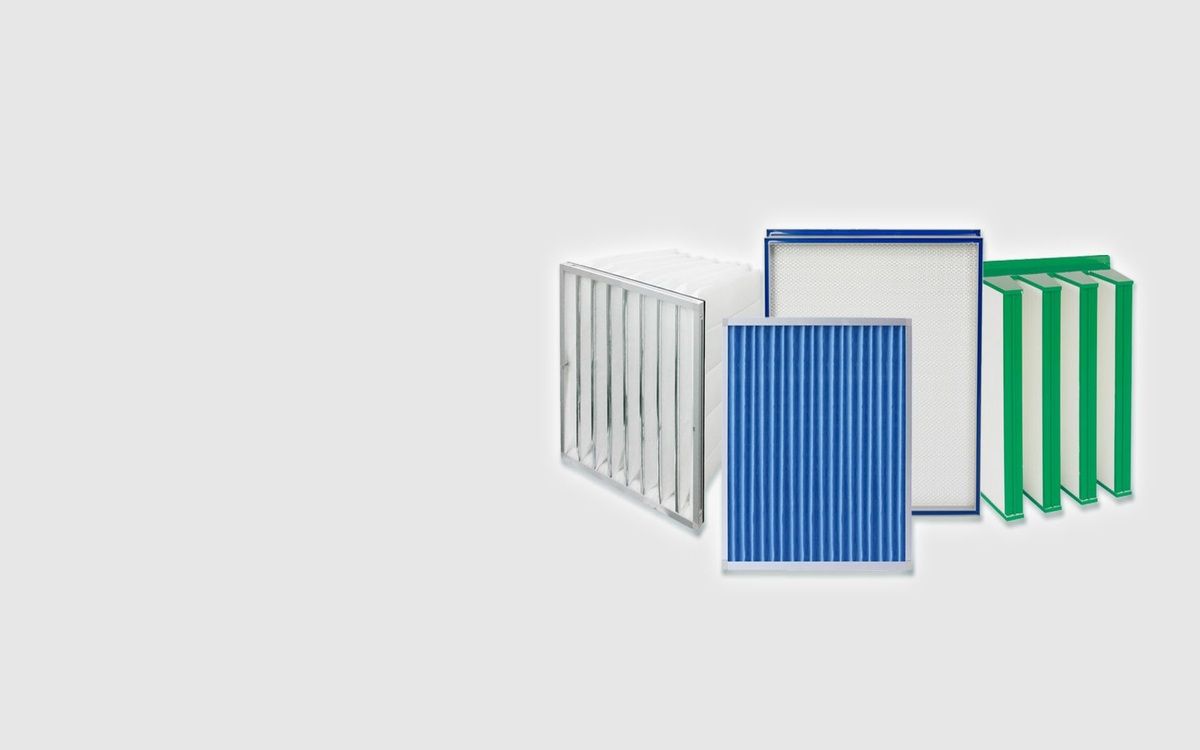

A typical air filtration system consists of multiple stages:

-

Pre‑filter: removes coarse dust particles, protecting further filter layers

-

Medium filter (F5–F9): traps finer dust and medium-sized bacteria

-

HEPA/ULPA filter (H13–U16): filters ultrafine particles down to 0.3 µm with > 99.97% efficiency

These filters are installed at various locations in HVAC systems: at AHU inlet, in ducting, or as ceiling‑mounted HEPA boxes, ensuring the cleanroom meets cleanliness levels.

Why must Air Filters comply with GMP?

GMP (Good Manufacturing Practices) establishes strict rules for microbial and particulate contamination control in production environments. If substandard filters are used:

-

Cleanliness standards may not be met → GMP audit failure

-

Cross‑contamination between zones may occur → product recall risk

-

HVAC load increases → higher operating costs

Thus, selecting an Air Filter is not just purchasing a device—it ensures the entire system operates in compliance, protecting product quality and the company’s reputation.

Read more: Air Filter Supplier — Air Filter Meeting GMP Standard

Standards in Pharmaceutical, Food, Cosmetic Industries

In controlled manufacturing environments (pharma, food, cosmetics), filters must not only remove dust but also meet international standards for performance, durability, and biosafety.

Common filter grades

Cleanroom air filtration systems often use 3–4 stages, from coarse to fine filtration, to balance performance and cost:

-

Pre-filter (G2–G4): coarse particles, fibers, large debris

-

Medium (M5–F9): fine dust, larger bacteria

-

HEPA (H13–H14): ≥ 99.97% removal for particles ≥ 0.3 µm

-

ULPA (U15–U17): extreme purification for ISO 4–5

Technical standards to adhere to

GMP‑compliant filters should follow:

-

EN 1822 (EU): Performance testing of HEPA/ULPA filters (DOP test)

-

ISO 16890 (international): Classification based on particulate removal (PM1, PM2.5, PM10)

-

EU / WHO GMP standards: Requirements on airborne particle control in critical zones

| Filter Type | Efficiency Grade | Removal Efficiency (EN 1822 / ISO 16890) | Typical Installation Location |

|---|---|---|---|

| Pre‑filter | G2–G4 | captures coarse dust >50 µm | AHU inlet, return air grilles |

| Medium | M5–F9 | captures PM10–PM2.5 range | before HEPA in HVAC train |

| HEPA | H13–H14 | ≥99.97% at ≥0.3 µm | ceiling HEPA boxes, FFUs |

| ULPA | U15–U17 | ≥99.9995% at ≥0.12 µm | ultra‑clean zones (ISO 4–5) |

Read more: Latest price list of HEPA filters used in medical clean rooms

3. Risks of Choosing the Wrong Air Filter Supplier

In a GMP environment, a low‑quality air filter can itself become a hidden contamination source, greatly affecting production and audit outcomes. Here are three major risks:

-

Filters failing tests → contamination, audit rejection

Some plants use filters without individual performance certification (e.g. DOP test). Consequences include inability to maintain cleanliness, particle/bio load exceeding limits, and failures in internal or external GMP audits. -

Lack of COA or certification → audit noncompliance

Some suppliers cannot provide:-

COA (Certificate of Analysis) from manufacturer

-

DOP / EN 1822 test reports

-

ISO 16890 / EN 1822 certifications

Without transparent certification, the plant cannot document proper equipment validation for GMP audits.

-

-

Poor maintenance service → pressure differential issues, reduced filter life

Even good filters degrade without proper service:-

Excess differential pressure → overloading HVAC fans

-

Leakage through cracks or damaged sealing

-

Higher operating costs and earlier replacement

-

Choosing a reliable supplier is not just product selection—it safeguards system integrity and GMP compliance.

Read more: Latest price list of HEPA filters used in food factories

4. VCR — A Specialized Supplier of GMP‑Standard Air Filters

With more than 10 years of experience in cleanroom systems, VCR Cleanroom Equipment is a strategic partner for hundreds of pharmaceutical, cosmetic, and food factories in Vietnam, supplying internationally standard air filters.

-

Full air filtration ecosystem — from pre‑filter to HEPA box

VCR offers not just individual filters but a full solution:-

Pre-filter (G3–G4) at AHU inlets

-

Medium filters (F5–F9)

-

HEPA filters (H13–H14) for ISO 7–8 zones

-

ULPA filters (U15–U17) for ultra-clean zones

-

HEPA Box / integrated FFU solutions

All are customizable to project dimensions and applications (weighing rooms, airlocks, filling zones, etc.).

-

-

Transparent documentation — GMP inspection ready

VCR commits to providing:-

COA for each filter model

-

Individual DOP / EN 1822 test reports

-

Clear origin certifications from reputable manufacturers (Korea, Japan, Taiwan, etc.)

This transparency simplifies client audit preparation and helps pass internal/external GMP assessments.

-

-

Industry‑specific technical consulting

Each industry has unique needs, and VCR provides tailored advice:-

Pharmaceutical: air filtration for weighing rooms, filling rooms per EU‑GMP

-

Food: filtration to prevent cross‑contamination in processing/packaging

-

Cosmetics: filters suited to ISO 22716 requirements

-

Electronics: anti‑static and clean air for ISO 5–6

VCR serves not only as a product vendor but as a long-term partner in achieving and maintaining GMP compliance.

-

Read more: Latest price list of Heat-resistant HEPA filters used in Cosmetic factories

5. Table: Classification of Air Filters by Industry Application

Selecting the proper filter type for each zone ensures cleanliness and cost efficiency. Below is VCR’s practical classification by industry:

| Industry | Installation Zone | Recommended Filter Type | Technical Notes |

|---|---|---|---|

| Pharmaceutical | Weighing room, airlock | HEPA H14 | Efficiency ≥ 99.995% per EN 1822 — meets EU‑GMP |

| Food | Processing, packaging | Medium G4 + HEPA H13 | Combined solution to mitigate cross‑contamination |

| Cosmetic | Filling, packaging | Pre-filter G4 + HEPA Box H13 | Matches ISO 22716 requirements |

Note: For plants with multiple clean levels, design a staged filter train (coarse → medium → fine) to reduce load on HEPA and extend HVAC lifespan

Read more: Latest price list of HEPA filter used in cosmetic factory

6. How to Inspect and Maintain Air Filters According to GMP

To sustain filtering performance and compliance under GMP, production facilities should establish a routine inspection and maintenance plan. Key guidelines:

| Filter Type | Recommended Replacement Interval | Applied Conditions |

|---|---|---|

| Pre-filter | Every 2–3 months | In moderate to dusty environments |

| Medium filter | Every 4–6 months | In conjunction with effective pre-filtering |

| HEPA filter | Every 6–12 months | Depending on ISO class (5–8) and usage frequency |

| ULPA filter | Every 12–18 months | For extremely clean zones (ISO 4–5) |

Beyond timing, monitor pressure differentials to optimize replacement points.

DOP test & differential pressure check

-

Performance test – DOP

-

Applicable to HEPA/ULPA filters

-

Use particle counting and DOP challenge to validate ≥99.97% efficiency (per EN 1822)

-

-

Pressure differential checks

-

Use a differential pressure gauge or sensor

-

Warning thresholds:

-

Pre-filter: > 100 Pa → clean or replace

-

HEPA: > 250–300 Pa → replace filter

-

-

Check at least once per month

-

Sample maintenance checklist

| Task | Frequency | Performed by |

|---|---|---|

| Check differential pressure | Weekly | HVAC technician |

| Clean / replace pre-filter | Every 2–3 months | Use compressed air or replace |

| Inspect HEPA Box sealing | Every 6 months | Ensure no leakage |

| Perform DOP test for HEPA | Every 12 months (or per GMP) | Internal or third‑party tester |

| Log maintenance records | Every time | For audit / validation records |

Proper testing and timely maintenance not only prolong filter life, but also preserve stable cleanliness levels—an essential requirement for GMP, HACCP, ISO 22716, etc.

Read more: Latest price list of HEPA filters used in electronics factories

7. Frequently Asked Questions About GMP‑Compliant Air Filters

Q1: What certifications must GMP air filters have?

GMP‑used air filters should include:

-

COA (Certificate of Analysis) from the manufacturer

-

DOP / EN 1822 test results showing ≥99.97% filtration efficiency

-

Clear origin certification, ideally from recognized manufacturers

Q2: How often should filters in pharmaceutical cleanrooms be replaced?

-

Pre-filter: every 2–3 months

-

HEPA filter: 6–12 months (depending on ISO class and usage)

If differential pressure unexpectedly rises, replacement may be needed sooner.

Q3: Does VCR support filter testing and inspection?

Yes. VCR provides on‑site GMP‑standard validation services including:

-

DOP tests

-

Differential pressure measurements through filter layers

-

Full maintenance documentation for audits

If you need GMP‑compliant Air Filters for pharmaceutical, food, or cosmetic factories, VCR is a reliable partner offering COA, DOP testing, clear origin, free consultation, fast delivery, and on‑site inspection support.

Contact details:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Dat VCR