HEPA (High Efficiency Particulate Air) filters are high-performance air filters that can remove up to 99.97% of 0.3 micron dust particles – a key factor in maintaining a standard electronics manufacturing environment. Updating the price of HEPA filters used in electronics factories helps businesses choose the right air filtration solution.

- 1. What is a HEPA filter and its role in electronics manufacturing plants?

- 2. Common types of HEPA filters used in electronics factories

- 3. Factors Affecting the Price of HEPA Filters

- 4. Latest HEPA Filter Price Update (2025) for Electronics Factories

- 5. Recommended HEPA Filter Selection by Production Area

- 6. FAQ - Frequently Asked Questions

- 7. Need a Quote for Certified HEPA Filters for Your Electronics Factory?

1. What is a HEPA filter and its role in electronics manufacturing plants?

What is a HEPA filter?

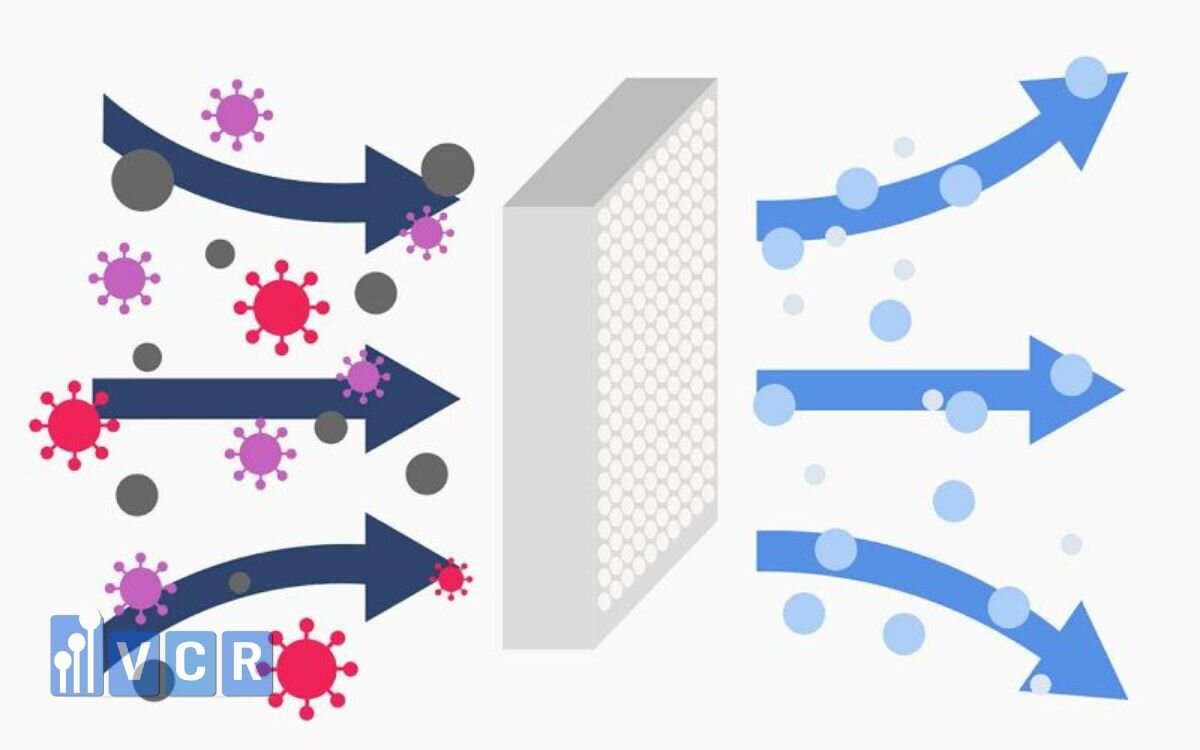

HEPA (High Efficiency Particulate Air) filters are high-efficiency air filtration units capable of removing at least 99.97% of airborne particles sized 0.3 microns, which is considered the most penetrating particle size in HVAC systems. HEPA filters are typically made from ultra-fine glass fiber arranged in pleats to maximize filtration area while minimizing airflow resistance.

Why are HEPA filters essential in electronics factories?

In electronics manufacturing environments such as semiconductors, SMT, AOI, PCB, ultra-fine dust, ionized particles, or electrostatic charges can cause:

- Circuit errors due to dust adhesion during assembly

- Component damage caused by contaminants affecting precision

- Short circuits or fire hazards due to static electricity buildup

HEPA filters help maintain the required cleanroom environment by minimizing airborne particles, fine dust, and microorganisms. They ensure high production quality and operational safety.

HEPA filters and ISO standards in electronics factories

Most electronics manufacturing plants adhere to ISO 14644-1 cleanroom standards, especially the following classifications:

|

Area |

Required ISO Cleanroom Class |

Recommended Filtration Equipment |

|

SMT, photolithography |

ISO 5 - ISO 6 |

FFU + HEPA H14 |

|

AOI room, final inspection |

ISO 6 - ISO 7 |

HEPA Box + Mini-pleat filter |

|

Airlock - gowning rooms |

ISO 7 |

Pre-filter + Panel HEPA filter |

HEPA filters play a central role in maintaining these cleanroom classes and are also mandatory for periodic air quality testing and certification processes.

2. Common types of HEPA filters used in electronics factories

In electronics facilities—where components are highly sensitive to fine particles and ionization—selecting the right type of HEPA filter for each area is critical. Below are the most commonly used types:

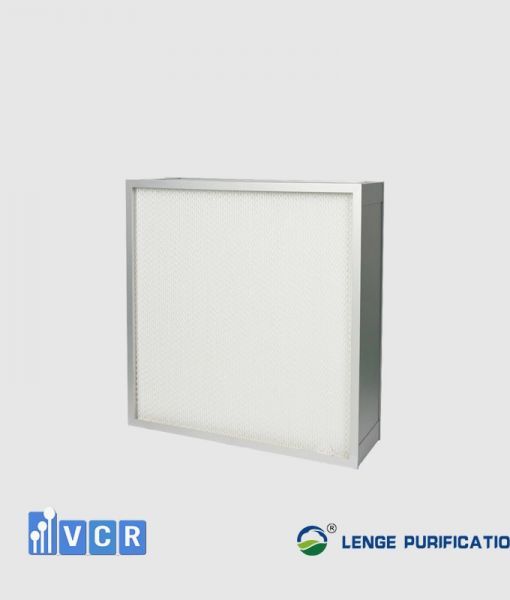

Panel HEPA filters

This is the most basic type, designed in a slim box format with aluminum or stainless steel frames. Due to their simple structure, panel HEPA filters are typically used in support areas such as gowning rooms, airlocks, or small HVAC systems.

Advantages: Low cost, easy replacement.

Limitations: Lower airflow capacity, not ideal for high-level cleanroom zones.

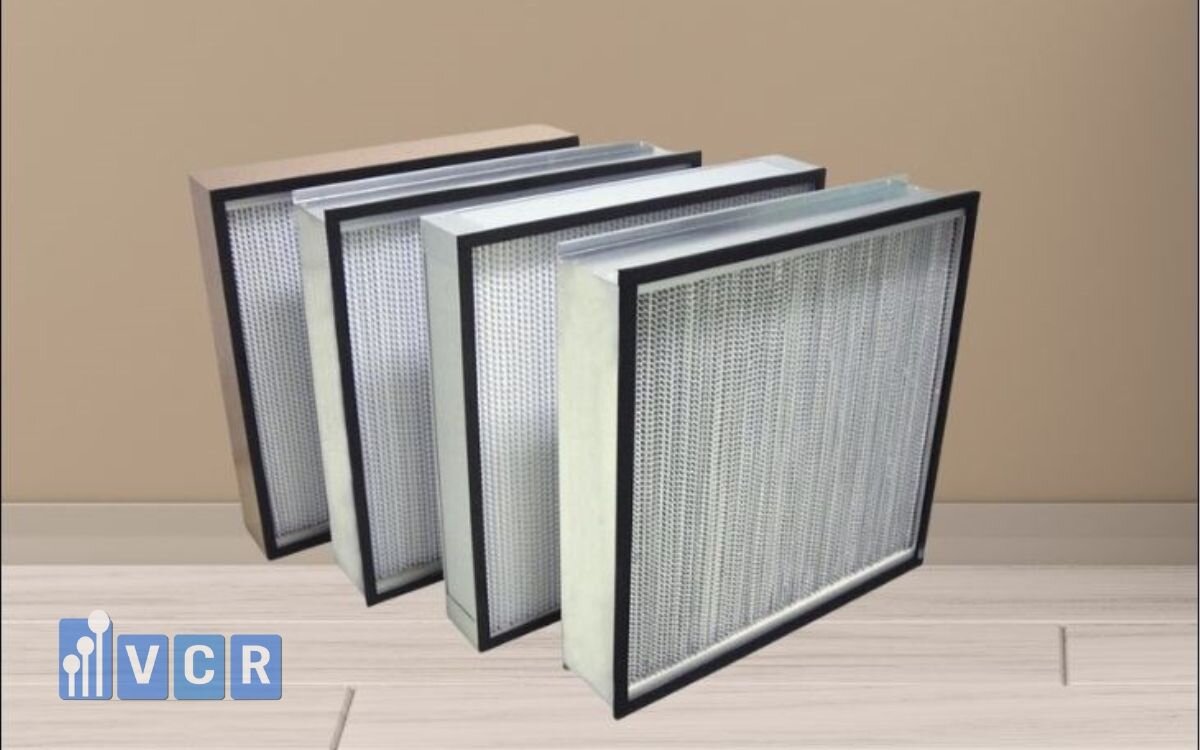

Mini-pleat HEPA filters

These filters are the most widely used in electronics manufacturing due to their densely pleated structure, which increases surface area without increasing physical size.

Commonly installed in Fan Filter Units (FFUs), ceiling-mounted HEPA boxes, or areas requiring medium to high airflow—such as AOI rooms or clean workstations.

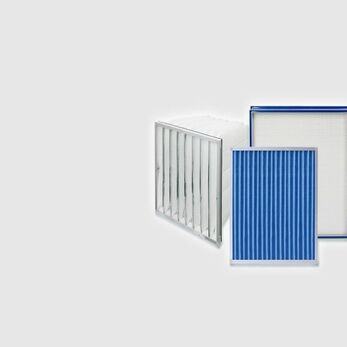

V-bank / V-cell HEPA filters

Constructed with multiple pleated layers in a V-shaped configuration, these filters handle large air volumes and are ideal for centralized AHU systems or SMT zones requiring continuous ISO 5-6 cleanliness.

Advantages: High airflow capacity, long service life, space-saving.

Note: Higher initial cost compared to panel filters.

HEPA integrated in HEPA Boxes or FFUs

This is an all-in-one solution, where the HEPA filter is pre-installed in a box (HEPA Box) or device equipped with a built-in fan (FFU). These systems are typically installed in the cleanroom ceiling or key production areas.

Advantages: Uniform airflow, easy leakage testing via DOP ports, convenient maintenance, and space optimization.

Each area in an electronics plant requires different types of HEPA filters depending on its function, cleanliness level, and technical requirements. Choosing the right combination helps ensure effective particle control and product protection.

3. Factors Affecting the Price of HEPA Filters

The price of a HEPA filter is not determined solely by its size or supplier, but also influenced by various technical and commercial factors. Here are the key aspects to consider when evaluating or comparing HEPA filter pricing:

Filtration Grade (H13, H14, U15…)

HEPA filters are classified according to EN 1822 standards, such as H13, H14, and U15. The higher the grade, the greater the filtration efficiency:

- Filtration efficiency ranges from 99.95% to 99.9995%

- Prices increase exponentially due to stricter manufacturing and quality control requirements

In electronics manufacturing, H14 is the most commonly used. For ultra-clean areas like photolithography, U15 may be required.

Country of Origin (China, Japan, Europe)

Product origin significantly impacts the final cost:

- China: Lower prices and faster lead time, but requires strict quality control

- Japan & South Korea: Higher prices but stable performance and longer lifespan

- Europe (Germany, Italy, etc.): Ideal for high-grade cleanrooms with strict requirements for CO/CQ and DOP testing

Filter Media (Glass Fiber, PTFE…)

Most HEPA filters use one of the following materials:

- Glass fiber paper: Most common, cost-effective, and stable in performance

- PTFE membrane: Better filtration, lower resistance, and moisture-resistant—but significantly more expensive

Choosing the right material depends on cost, durability, and specific operating environments.

Order Quantity (Retail vs. Project-based)

Suppliers typically offer volume discounts:

- Small quantities (1-5 units): Higher unit prices, often without included testing

- Bulk/project orders (20-100 units): Discounts of 15-30%, with on-site testing and technical support often included

Customization Based on Factory Requirements

If the factory needs filters with non-standard sizes, rounded corners, double gaskets, DOP ports, or custom mounting, the supplier will need to design and manufacture accordingly. This can increase the cost by 10-25% compared to standard models.

Customization also requires longer lead times and technical drawing approval, so early planning is essential.

Understanding these factors helps electronics manufacturers choose HEPA filters that fit their budget while meeting technical standards—avoiding over- or under-spec purchases that could impact cleanroom compliance.

4. Latest HEPA Filter Price Update (2025) for Electronics Factories

|

HEPA Filter Type |

Common Specifications |

Application |

Price Range (VND) |

Notes |

|

Mini-pleat H13/H14 |

610x610x90 mm |

FFU, HEPA Box, AOI rooms |

1,800,000 - 2,500,000 |

Optional: double gasket, DOP port |

|

V-bank H13/H14 |

592x592x292 mm |

AHU for SMT areas |

2,900,000 - 3,600,000 |

Higher cost for imported materials |

|

Integrated HEPA Box H14 |

Ceiling-mount with frame & DOP port |

ISO 5-6 cleanroom ceilings |

4,500,000 - 6,000,000 |

Includes box frame, diffuser, filter, DOP access |

|

Custom-size filters |

300x600 / 457x457 mm |

Workstations, filter hoods |

1,500,000 - 2,000,000 |

Customizable to match equipment dimensions |

|

ULPA U15+ Filters |

As specified |

ISO 4 cleanrooms |

6,000,000 - 8,000,000 |

Strict performance testing required |

Note: Prices may vary depending on order quantity, cleanroom grade, payment terms, and material origin (China, Japan, EU, etc.)

5. Recommended HEPA Filter Selection by Production Area

Choosing the right type of HEPA filter for each area not only ensures compliance with ISO 14644 cleanroom standards, but also optimizes operational efficiency and maintenance costs. Below are typical recommendations for key zones in an electronics manufacturing plant:

SMT Area (Surface Mount Technology)

- Characteristics: Produces microelectronic components highly sensitive to fine dust and static electricity

- Recommended filter: Ceiling-mounted FFU with H14 HEPA or V-bank H13 for high airflow

- Cleanroom classification target: ISO 5-6

AOI Room, Final Inspection Zone

- Characteristics: Requires clear lighting and consistent cleanliness for accurate inspection

- Recommended filter: HEPA Box with mini-pleat H14 filter, installed per ceiling grid or work zone

- Cleanroom classification target: ISO 6-7

Gowning Room - Airlock - Transitional Hallways

- Characteristics: Transition zones with high contamination risk if uncontrolled

- Recommended filter: Panel HEPA H13 filter combined with G4 pre-filter, installed at air transfer points or air showers

- Cleanroom classification target: ISO 7

Technical Rooms - Component Storage

- Characteristics: Lower cleanliness requirements, but still need protection for sensitive parts

- Recommended filter: Standard HEPA H13 filter, small size, easy to replace, optionally paired with F5 coarse filter

- Cleanroom classification target: ISO 8

Special Areas: Photolithography Rooms, Ultra-Clean Chambers

- Characteristics: Require extremely high cleanliness, typically Class 100 or better

- Recommended filter: ULPA U15 or higher, with full DOP validation, integrated into dedicated HVAC systems

- Cleanroom classification target: ISO 4-5

Each area in an electronics plant demands different HEPA filter specifications in terms of filtration grade, airflow capacity, and installation type. Choosing the wrong filter can severely affect production quality and ISO/GMP validation processes.

6. FAQ - Frequently Asked Questions

How often should HEPA filters be replaced in an electronics factory?

Typically every 6 to 12 months, depending on usage intensity, airborne dust levels, and actual filtration performance. For ISO 5-6 areas, quarterly checks are recommended, with early replacement if filters show clogging or excessive pressure drop.

Is DOP testing required for HEPA filters?

Yes, especially in high-precision electronic manufacturing. DOP testing verifies real-world filtration efficiency and detects any particle leakage. It is usually performed before system commissioning and repeated every 6 months.

Are Chinese-made HEPA filters reliable?

Yes, if they are properly certified. Some Chinese filters offer good performance and cost-efficiency, but it's essential to verify CO/CQ documentation and conduct on-site DOP testing to ensure quality.

Can HEPA filters be reused after cleaning?

No. HEPA filters are single-use devices. Washing or vacuuming them can damage the fiber structure and degrade performance. Reusing filters may compromise cleanliness levels and lead to product defects.

Should I choose H13 or H14 filters for my electronics facility?

For critical areas like SMT, AOI, and final inspection, H14 filters are the standard. For support zones or lower cleanliness requirements, H13 filters are sufficient and 10-15% more cost-effective.

7. Need a Quote for Certified HEPA Filters for Your Electronics Factory?

VCR is a trusted supplier of genuine HEPA filters tailored for electronics manufacturing - from FFUs and HEPA Boxes to V-bank and ULPA filters. We guarantee:

Certified grades H13, H14, U15

Full CO/CQ documents - on-site DOP testing available

Transparent pricing and volume discounts for projects

On-site technical support - installation and performance validation

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Diep VCR