A cleanroom carbon filter is the “invisible shield” that helps a cleanroom remove solvent vapors, chemical odors and volatile organic compounds. Thanks to a strong adsorption mechanism, this device plays a crucial role in maintaining air quality in accordance with GMP and ISO 14644 standards—and protecting products from gaseous contamination.

- What is an activated carbon filter?

- Why use an activated carbon filter in a cleanroom?

- When should you use an activated carbon filter?

- Criteria for selecting a suitable activated carbon filter

- How to install and maintain an activated carbon filter

- Notes on using activated carbon filters in a cleanroom environment

- Frequently asked questions about activated carbon filters in cleanrooms

What is an activated carbon filter?

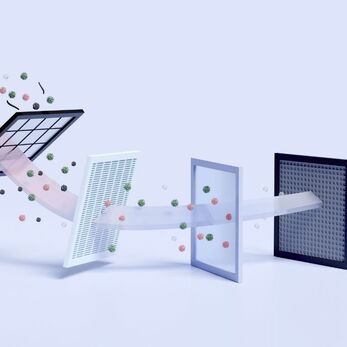

An activated carbon filter is a device designed to treat gaseous contaminants in the air-such as solvent vapors, chemical odors, and volatile organic compounds (VOCs)-within a cleanroom environment. Unlike HEPA or ULPA filters which specialize in removing fine particles and suspended particles, the carbon filter works based on an adsorption principle to remove unwanted gases.

A standard cleanroom activated carbon filter typically consists of:

-

A layer of activated carbon: either in granular or block form, processed from natural materials such as coconut shell, wood, bituminous coal… with a microporous structure that increases the surface area for contact.

-

A metal or technical plastic shell: to protect the carbon layer from mechanical impact and prevent dust leakage into the environment.

-

A pre-filter mesh: installed in front to trap large dust particles, helping to protect and extend the life of the activated carbon.

Mechanism of operation:

Physical adsorption: Pollutant gas molecules are held on the surface of the carbon by Van der Waals forces-commonly used to remove VOCs and light solvent odors.

Chemical adsorption: Some carbon types are impregnated with catalysts (e.g., KMnO₄, phosphoric acid…) to chemically react with more potent toxic gases such as formaldehyde, SO₂, NOₓ …

Thanks to its high adsorption capacity, the activated carbon filter plays an essential role in maintaining air quality in cleanrooms-where gas contamination control is extremely stringent.

Why use an activated carbon filter in a cleanroom?

In a cleanroom, controlling fine particles is a priority-but controlling dust alone is not enough. Many industries such as pharmaceuticals, food, electronics or cosmetics also generate various gas kinds and chemical vapors during production. Such gases can impact product quality, environment stability and the health of staff. That is why an activated carbon filter becomes an indispensable part of the HVAC system for many modern cleanrooms.

HEPA and ULPA filters are very effective at capturing fine particles, microorganisms and ultra-fine suspended particles, but they cannot handle toxic gases or chemical odors. Substances like VOCs (volatile organic compounds), ozone, formaldehyde … are gas molecules that can easily pass through fiber membranes of HEPA. To handle these gases, an adsorption solution is required-and activated carbon is the optimal choice.

Activated carbon effectively controls these hazard factors:

-

Chemical odors (IPA, ethanol, acetone…): In sterilization, cleaning or weighing processes, solvent vapors are not only unpleasant but can affect staff perception and distort analytical results (in labs).

-

Solvent vapors in production: Electronics, cosmetics, coating industries use many types of high-toxicity solvents. If not properly treated, these gases can adhere to products, causing defects or chemical instability.

-

Toxic VOCs and other air pollutants: VOCs are easily volatilised at room temperature, can accumulate in the air causing headaches, eye irritation, dizziness and long-term effects on liver, kidney and nervous system. Activated carbon can adsorb VOCs thanks to its porous structure and large surface area.

If these gases are not properly treated, outcomes may include: -

Damage to sensitive equipment in the cleanroom

-

Impact on chemical reaction stability

-

Increase in product defect/failure rate

-

Increased health risk for operation staff

Integrating an activated carbon filter into the HVAC system not only protects the cleanroom environment from toxic gases but also forms part of a comprehensive quality-control strategy for modern factories.

When should you use an activated carbon filter?

An activated carbon filter is not always a mandatory component in a cleanroom system. However, in the following specific cases, its use is essential to ensure safety, regulatory compliance and product protection:

Situations requiring use:

-

Pharmaceutical cleanrooms using extraction solvents: Many extraction, API-preparation processes use ethanol, methanol or acetone. These solvents generate easily volatile VOCs that cannot be removed by standard HEPA filters. Activated carbon helps efficiently adsorb them, avoiding cross-contamination and impact on pharmaceuticals.

-

Food-industry plants using ozone or ethylene oxide sterilisation: Ozone and EO are strong sterilising agents but also toxic gases if residual remains. The activated carbon filter helps adsorb these gases after sterilisation, ensuring they do not disperse into the production environment.

-

Electronics workshops using adhesives, plastics or soldering: In PCB, chip or component production, many adhesives and plastics contain toluene, xylene and other toxic VOCs. Activated carbon filters help clean the air, prevent corrosion of components and protect the health of workers.

-

Chemical analysis laboratories: Operations like extraction, chromatography often use organic solvents and volatile acids. The activated carbon filter helps process the gaseous compounds generated, maintaining cleanliness and safety for both equipment and personnel.

Signs indicating that an activated carbon filter is needed:

Even if a system already has HEPA/ULPA filters installed, you should consider adding activated carbon if the following signs occur:

-

Persistent chemical odor: The air has a strange odor or chemical smell even after filtering. This clearly indicates the current filtering system cannot handle VOCs.

-

Staff discomfort: Reports of headaches, eye irritation, dizziness-indicating exposure to low-level gases over time. Activated carbon will help reduce the harmful agents.

-

Measured gas concentrations exceed standards: If monitoring detects VOCs, ozone or other chemical gases beyond thresholds, then supplementary adsorption filters become mandatory.

Criteria for selecting a suitable activated carbon filter

Choosing the right activated carbon filter does not only help handle gaseous pollutants efficiently but also ensures the HVAC system operates stably and maintenance costs are reduced.

Key criteria:

Airflow and installation size:

- Each cleanroom has different airflow requirements (CFM or m³/h), which directly affect the processing speed of the filter.

- If you choose a filter with capacity lower than actual airflow, adsorption ability will not meet the requirement and toxic gas may accumulate.

- The physical size of the filter must also be compatible with the mounting location in the HVAC system or dedicated filter housing.

- Recommendation: Check detailed system specifications to select the correct filter model.

Type of gas to be treated – choose the right carbon material:

- Depending on the characteristics of the polluted gas in the cleanroom, you need to choose a specialist activated carbon type for highest effectiveness.

- For example: solvent vapors (IPA, ethanol, acetone…) → standard granular or honey-comb activated carbon; acidic gases (SO₂, HCl…) → carbon impregnated with NaOH or KMnO₄; alkaline gases (ammonia, NH₃) → acid-impregnated or catalytic carbon; light food/chemical odors → standard activated carbon. If unclear about gas type, measure VOC concentrations or refer to MSDS of raw materials to determine accurately.

Service life – replacement cycle depending on gas load:

- The lifespan of an activated carbon filter typically ranges from 3 to 6 months, depending on:

-

-

-

The inlet concentration of pollutants

-

Daily operating hours of the system

-

Type of carbon and structure of the filter

-

-

- When the carbon is saturated, adsorption capacity is nearly zero-continuing to use will allow toxic gases to leak into the environment.

- Recommendation: Set up a regular inspection schedule and replace based on actual operational data.

Compatibility with the existing HVAC system:

- Some cleanroom HVAC or AHU systems are small and only allow filters of specific size (e.g., 610×610×292 mm).

- Also need to check:

-

-

Pressure drop: The filter must not cause excessive flow resistance.

-

Installation location: Before or after HEPA filter? Is maintenance access convenient?

-

-

- If modifications are needed, work with supplier to design a suitable filter module.

How to install and maintain an activated carbon filter

Installation location in the cleanroom air-filtration system:

The activated carbon filter is typically installed at an intermediate stage, specifically:

- After the pre-filter: to ensure large dust particles do not stick to the carbon surface and reduce adsorption efficiency.

- Before HEPA/ULPA filter: to protect the fine filter from chemical vapors or corrosive gases, extending the life of the main filter layers.

Correct placement helps optimize airflow, maintain treatment efficiency for both dust and toxic gases.

Periodic check of inlet-to-outlet gas concentrations:

To evaluate adsorption effectiveness, you need to measure:

- Concentration of VOCs, odors or hazardous gases at filter inlet and outlet.

- Common devices: VOC sensors, formaldehyde meters, ozone meters…

- Comparing before-and-after values helps determine operational status and when replacement is needed.

Clean or replace filter core on correct cycle:

Depending on the carbon type and usage level, the filter may require:

- Full replacement: after 3-6 months (under continuous operation).

- Regeneration (for reusable carbon types):

-

-

-

Drying at recommended temperature

-

Limit number of reuse cycles because adsorption efficiency gradually reduces.

-

-

- Note: If odors or VOCs persist after regeneration, the core must be replaced to ensure cleanroom standards.

Keep full maintenance log:

Maintaining a log helps control operational efficiency:

- Installation and replacement time

- Periodic gas concentration measurement results

- Feedback from staff about air quality

- Differential pressure levels (if any) in the system

Documenting this not only supports maintenance but also internal quality audits or GMP/ISO assessments.

Notes on using activated carbon filters in a cleanroom environment

Do not replace HEPA/ULPA – only use as a supplement for gas treatment:

Activated carbon filters cannot remove ultra-fine particles or microorganisms-that job belongs to HEPA or ULPA filters. Carbon filters only adsorb toxic gases, solvent vapors or chemical odors. Therefore, in a cleanroom environment, activated carbon should be used as a supplementary filter, not a replacement for the main particle filter. Using only activated carbon will fail to meet comprehensive air-filtration standards.

Avoid exposure to water or hot steam:

Activated carbon is very sensitive to humidity. If exposed to water or hot steam, the adsorptive surface becomes sealed, losing the ability to capture toxic gases. Furthermore, moisture may lead to mold growth in the filter core, causing secondary contamination in the cleanroom. Therefore, the activated carbon filter should be installed in a dry location, preferably after any dehumidification equipment, and away from humidity-generating sources in the HVAC system.

Monitor filter lifespan – when carbon is saturated, adsorption efficiency drops sharply:

When the voids on the carbon surface are filled with adsorbed gas molecules, the ability to treat odors and VOCs falls significantly. This is called the saturation state-continuing to use it may allow toxic gases to reverse into the cleanroom. Therefore, set up a regular monitoring schedule, combining devices to measure gas concentrations or odor sensors to evaluate actual filter performance and determine replacement timing.

Use in combination with supporting solutions like air showers, sealed HVAC systems:

Installing only an activated carbon filter is not enough if the cleanroom does not ensure optimal operating conditions. To maximise effectiveness, you should combine:

- An air-shower: to remove dust and solvent vapors from personnel and materials before entering the cleanroom.

- A sealed, pressure-balanced HVAC system: to reduce the chance of contaminated air infiltration and prevent discharge of chemical vapors into adjacent areas.

- Multi-stage filters: place activated carbon between primary, intermediate and HEPA filter stages to improve effectiveness and filter life.

When combined correctly, the activated carbon filter will help elevate the cleanroom’s air quality, protecting both the product and the health of workers.

Frequently asked questions about activated carbon filters in cleanrooms

Can an activated carbon filter be used in an ISO 5 cleanroom?

Yes, an activated carbon filter can absolutely be used in a high-level cleanroom such as ISO 5, provided certain technical conditions are met:

-

Sealed design, no secondary dust generation: The carbon core must be enclosed in a metal or plastic housing of appropriate standard to prevent carbon leakage into the environment.

-

Compatible with laminar airflow: The filter must not disturb the unidirectional airflow in high-cleanliness areas.

-

Does not cause contamination: The materials must not emit VOCs or react with chemicals in the cleanroom environment.

When properly integrated, the activated carbon filter can handle odors, VOCs while still maintaining the stringent cleanliness level of ISO 5.

How do you know when to replace the activated carbon filter?

Replacing the activated carbon filter at the correct time is very important to ensure gas adsorption efficiency and odor removal:

-

Based on operating time: On average each filter core has a lifespan from 3-6 months, depending on gas load and environment conditions.

-

User perception: If chemical odor returns despite the dust filtering system still functioning normally, the carbon core may be saturated.

-

Measured by devices: Use VOC measurement devices to check gas concentrations before and after the filter. If adsorption efficiency drops below 70%, replacement is needed immediately.

Scheduling regular checks is the optimal method to avoid undetected filter degradation.

Can you use an activated carbon filter in conjunction with HEPA?

Yes. In fact, this is the ideal air-filtration solution in a cleanroom:

-

HEPA/ULPA filters specialize in removing ultra-fine particles such as bacteria, nano-dust…

-

Activated carbon filters treat toxic gases, solvent vapors, chemical odors that HEPA cannot absorb.

The common design is: Pre-filter → Activated Carbon → HEPA/ULPA.

This helps extend HEPA lifespan and ensures more comprehensive air quality.

Is an activated carbon filter reusable?

Answer: It depends:

-

Some activated carbon types can be regenerated by heat or chemical treatment. However, this process:

-

Is complex

-

Is expensive

-

Does not guarantee the same performance as originally

-

-

Most current cleanroom systems prefer to replace the core every 3-6 months to ensure stability and highest safety.

Thus, unless you have a dedicated regeneration system, the recommendation is to replace according to the manufacturer’s recommended cycle.

Are you dealing with chemical odors, solvent vapors or VOCs in your cleanroom? An activated carbon filter is the solution that helps improve air quality and protect both employee health and product stability.

-

Consult for selecting the right filter for each industry: pharmaceutical, food, electronics, cosmetics

-

Wide range of carbon types: honey-comb, KMnO₄-impregnated, granular

- On-site installation and maintenance support

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://airfilter.vn/

Dat VCR